Morphing is One Way to Make Aircraft More Efficient (Op-Ed)

This article was originally published at The Conversation. The publication contributed the article to Live Science's Expert Voices: Op-Ed & Insights.

It is estimated that by 2050 there will be a six-fold increase in the number of flights there are today. This is going to be an environmental problem, and it will need radical change in aircraft design to deal with it.

Over the past 50 years, as the world has become more interconnected, the annual growth rate of the number of flights within Europe has remained consistent at 3.9%. The rise of Asia and cheap flight carriers, like Ryanair, making weekend trips away affordable to the masses have pushed the rate up. This is expected to level out at 5.3%.

Not only is the air transport industry the fastest growing within the transport sector, it is historically the hardest to make greener. The transport sector as a whole is increasing CO2 emissions at such a rate that it has cancelled out two decades' worth of green gains made across the manufacturing, power generation, district heating, residential, services and agriculture sectors combined. This devastating disparity is forecast to grow.

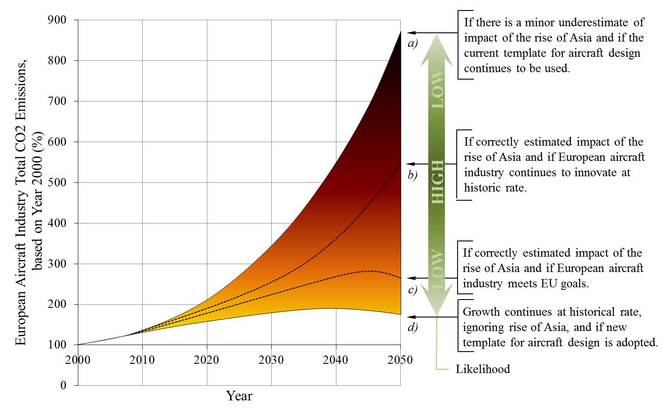

The goal set by the EU to reduce aircraft CO2 emissions by 75% by 2050 is totally unrealistic. Even if Europe were to meet these goals, its aircraft industry will at the very least double its greenhouse emissions by 2050. The bleak reality is that we will probably see a quadrupling in the aircraft industry CO2 emissions by then – unless it totally reinvents the concept of the commercial aircraft.

Boeing and Airbus both claim their aircraft are up to 20% more efficient than their “nearest competitors” or more hazily “similarly sized airplanes”, but the numbers just don’t add up. Today’s new aircraft are approximately 5% to 10% more fuel efficient than the previous generation. The effect of green innovations have been dulled by the increase in aircraft weight per passenger with, for example, the introduction of burdensome interiors like hefty entertainment systems or a sit-down drinks bar in the Business Class Lounge.

Back to nature

The past decade has shown the least improvement in aircraft fuel efficiency when compared to advances over the past century. The “tube and wing” template we use is a fossil. It is constrained by limitations that no longer exist today. Though we have near perfected aircraft design within this template, the template itself does no justice to what nature has achieved when considering flight efficiency.

Get the world’s most fascinating discoveries delivered straight to your inbox.

Inspiration from nature, along with the complexity made possible in manufacture through methods such as 3D printing, has allowed new ideas to flourish. As Mike Griffin, President of AIAA, stated at SciTech 2014, “Biology is becoming the new basis for technology.”

There are an untold number of inventions and innovations hidden within nature. As Richard Feynman put it, “Nature’s imagination is so much greater than man’s, she’s never going to let us relax.”

The future

As rigid structures, aircraft today are intrinsically built to fly efficiently at one hypothetical point: at a certain speed, altitude, temperature. Stray from that point and aircraft fuel efficiency drops as the aerodynamics have changed.

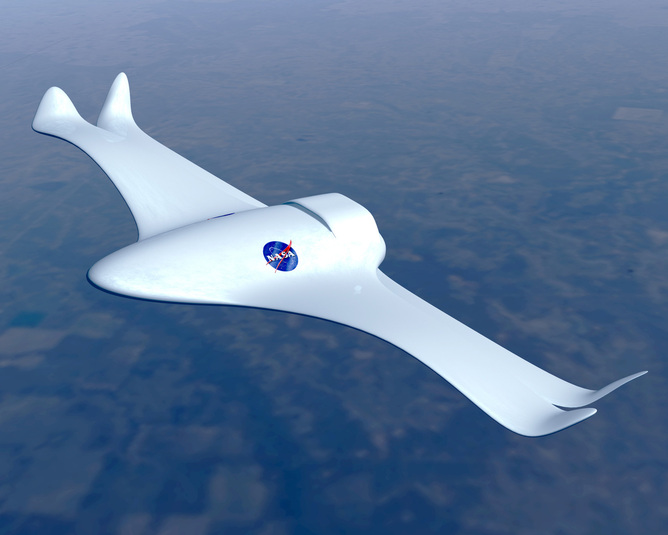

Allowing the parameters of an aircraft’s geometry to become adjustable during flight would lead to large gains in efficiency throughout the flight envelope – that is, from take-off to landing. This is the idea behind aircraft morphing. Research suggests that by allowing for variations in wing span and width during flight, with for example morphing honeycomb structures, a typical commercial flight would be approximately 20% more aerodynamically efficient.

Morphing means tailoring the shape of the aircraft to best fit the objective at hand – be it maximising fuel efficiency, speed or manoeuvrability. Examples of morphing devices are found in commercial aircraft today, including retractable undercarriages and wing flaps.

Though morphing technologies have shown to be promising in academic circles, the industry is yet to tap into it. Changing the template, and therefore the game, requires a great deal of investment. Industry has not yet been motivated by the threat of taxes or changes in legislation.

As the famous aircraft designer Sir Sydney Camm claimed: “All modern aircraft have four dimensions: span, length, height and politics.”

Morphing technologies may not be the sole solution to the problem we are facing, but they will play an important role. All-electric propulsion, energy harvesting systems, prolific use of light-weight composite materials, and formation flying will all go some way to resolving the issue.

Adoption of a new aircraft technology, from sketches to research to testing to full integration, is typically a decade-long process. The situation is desperate. Unless we accept that flights of the future will be restricted to the wealthy, we are in dire need of a paradigm shift in the way we fundamentally design aircraft.

Ashley Dale does not work for, consult to, own shares in or receive funding from any company or organisation that would benefit from this article, and has no relevant affiliations.

This article was originally published on The Conversation. Read the original article. The views expressed are those of the author and do not necessarily reflect the views of the publisher. This version of the article was originally published on Live Science.

Live Science Plus

Live Science Plus