Transparent Material Could Lead to Disposable Electronics

A new material designed for producing bendable transistors is practically invisible and simple to produce. It could lead to a new class of throwaway electronic devices, its inventors say.

The "thin-film" material is not expected to replace existing silicon-based computer products. But it could be used for foldable electronic devices, improved flat-panel displays, or game players that no one has thought of yet. An entire windshield could be turned into a see-through electronic setup with built-in visual displays.

The research was led by John Wager, a professor of electrical and computer engineering at Oregon State University.

Durable and flexible

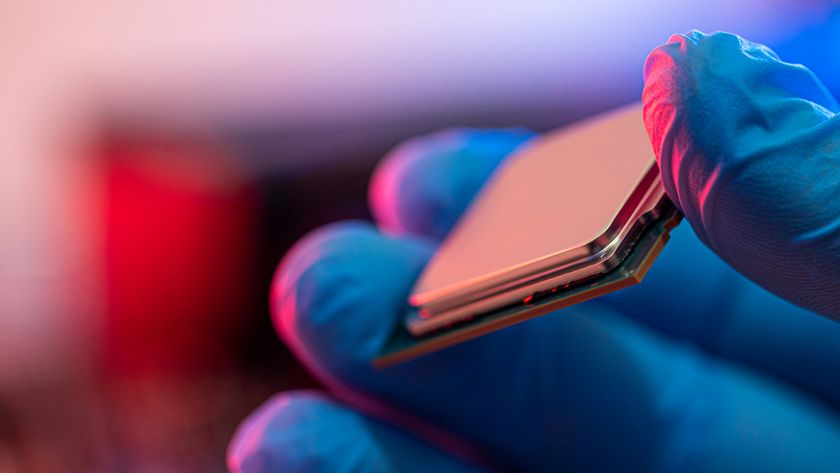

Transistors are miniature electronic switches that serve as the backbones of computers and other electronic devices. Other attempts to make thin-film transistors have involved polymers and organic materials, typically carbon based. Think of them as being something like soft plastic, Wager said. You could cut them with scissors, and they have to be encapsulated to protect them from water vapor.

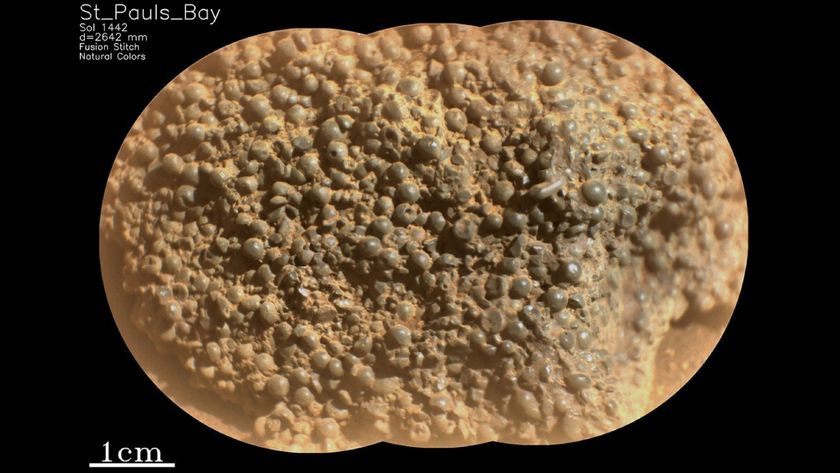

Embedded in this glass substrate are dozens of patterns created with an early version of the new material. Because the stuff is transparent, you see only the quarter underneath. Credit: John Wagner

The new materials are inorganic. One is made of a mix of zinc and tin. The stuff is hard, Wager told LiveScience, yet remains flexible and transparent.

"You have to press really hard to scratch it with scissors," he said. "You can dunk it in any solution you want, even strong acids."

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

Quick development

Wager said the material could be developed for commercial use in one to three years, assuming there is interest in the industry. That interest may not be hard to find. Scientist at Hewlett Packard contributed to the study.

"HP is excited about the possibilities that this development may enable, especially for our customers in imaging and printing," said Tim Weber, director of the company's Advanced Materials and Processes Laboratory.

Wager said most researchers didn't think the materials, now known formally as amorphous heavy-metal cation multicomponent oxides, could be made flexible. Even he is surprised at how the research has progressed. "It's come faster and more furious than I would have guessed two years ago," he said.

A potentially significant benefit of the material is that it can be produced at relatively low temperatures, not far above room temperature, Wager said in a telephone interview.

"That's shocking," he said. "Most integrated circuits made today, by comparison, are produced at temperatures between 700-1,100 degrees centigrade."

The results are published in the Jan. 3 issue of the journal Applied Physics Letters. The work was funded by the National Science Foundation and Army Research Office.

Robert is an independent health and science journalist and writer based in Phoenix, Arizona. He is a former editor-in-chief of Live Science with over 20 years of experience as a reporter and editor. He has worked on websites such as Space.com and Tom's Guide, and is a contributor on Medium, covering how we age and how to optimize the mind and body through time. He has a journalism degree from Humboldt State University in California.