3-D Home Printers Could Change Economy

When your favorite gadget of the future breaks, you might select a replacement model online, download its design file and make a true 3-D replacement on your home printer.

Thanks to falling prices and wider application of an industrial technology called 3-D printing (among other things), this option might be a reality for consumers in a few years.

Instead of stamping or casting to create objects using tools, dies and forms that were laboriously created for the task, each object is basically printed—built thin layer by thin layer directly from a computer-aided design, or CAD, file using various high-accuracy deposition methods.

Sintering, for instance, deposits layers of fine particles that are heated until they bind to adjacent particles. Stereo-lithography, meanwhile, uses a laser to harden a layer of an object on the surface of a pool of special resin. The object is then lowered slightly, and the next layer is created. Altogether, 3-D printing technologies can create things out of plastics, metal and ceramics, and some methods can add photo-realistic coloring.

More importantly, prices for 3-D printing machines have been falling rapidly, reaching $20,000, and the day is foreseeable when they will fall below $1,000 and become home appliances, says Phil Anderson of the School of Theoretical and Applied Science at Ramapo College in New Jersey.

The results, he warned, could be economically "disruptive."

"If you can make what you need in your own home quickly, then manufacturers become designers, with no need for factories, warehouses or shipping," Anderson told LiveScience.

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

Drawbacks to 3-D printing include time (aside from creating the data file, each object takes several hours to print and then usually requires additional curing), power consumption (metal objects especially require a lot of heat), size (current low-end machines have a work-space measuring 10 inches per side, so that anything larger would have to be made in segments) and the price of the specialized raw material.

Accuracy, surface finish and strength are not yet as good at the low-end as at the high-end, says industrial consultant Terry Wohlers.

3-D printers cheap enough for the home market could appear in four or five years, Wohlers said, though Anderson puts that figure at 15 years. However, that does not mean they will be in every home, churning out kitchenware or car parts on demand.

Other than dedicated tinkerers, video gamers will be the initial consumer market, Wohlers said.

"There are millions of people playing video games that often involve the creation of elaborate action figures," he noted. "I think the first wave will be the addition of a button to those games that says 'build me.' The figure would arrive in the mail, and you could get a six-inch figure for $25 to $100."

Today, making a figurine through a 3-D printing service bureau could cost something on the order of $500, but Wohlers expects volume would drive costs down considerably.

'We're already on the precipice of disaster': Deadly measles outbreaks could explode across the US in the next 25 years if vaccinations fall, model predicts

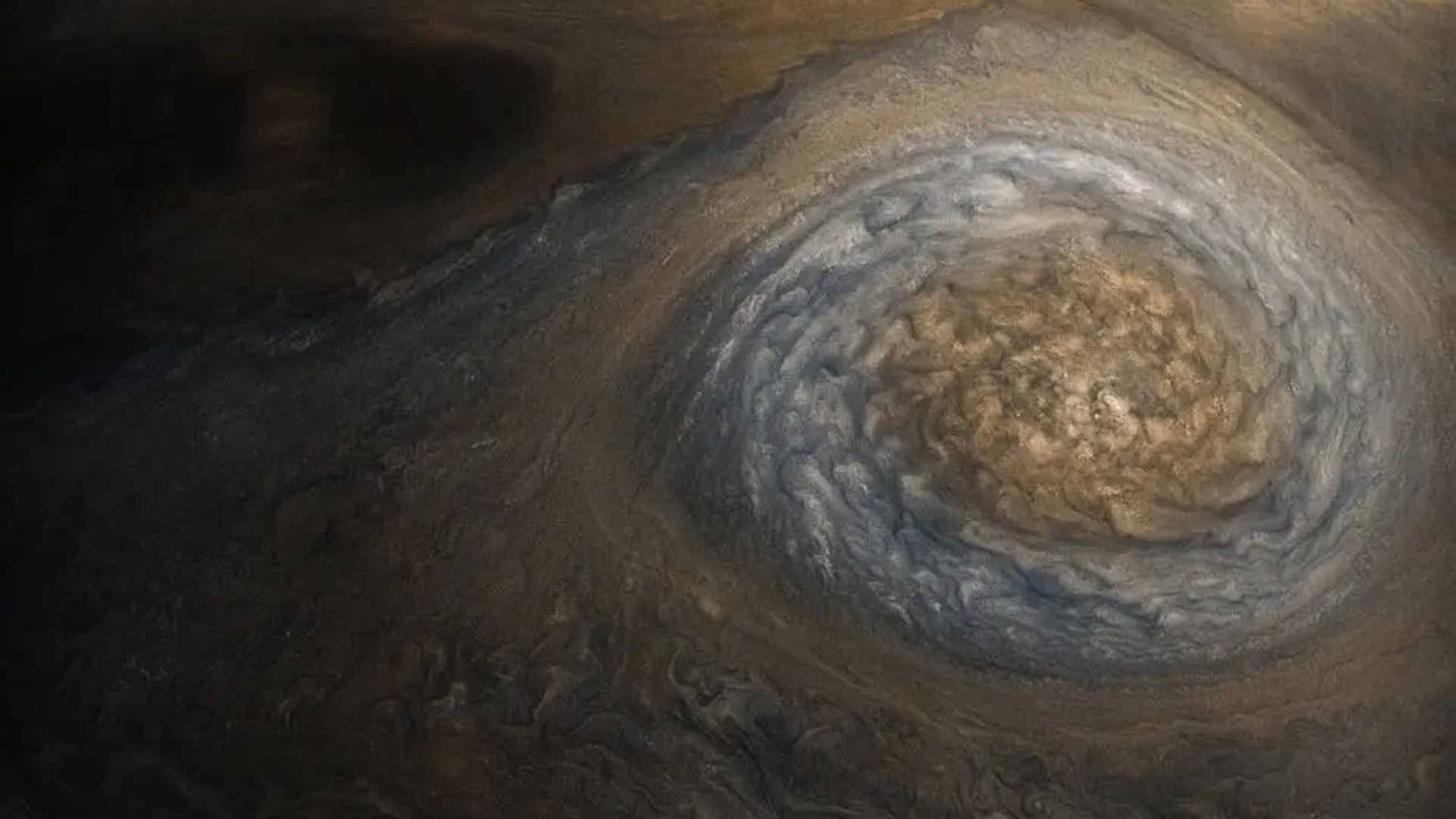

Cloudy with a chance of mushballs: Jupiter's monster storms include softball size hailstones made of ammonia

Tomb of ancient Egyptian prince discovered at Saqqara — and it has a giant 'false' pink door