Edible Oil Dispersant Tackles Spill Cleanup Problem

A new oil dispersant made primarily of edible ingredients could provide a more environmentally friendly way to clean up slicks and spills like the Deepwater Horizon disaster, scientists say.

The new dispersant, developed by scientists at the University of Southern Mississippi (USM), also floats, an important consideration when thinking about what happens to the droplets of "dispersed" oil.

Lisa Kemp, a research scientist at USM, presented the findings at the American Chemical Society's fall meeting in Philadelphia today.

Reached by phone before her presentation, Kemp explained that the primary ingredients in the new dispersant are a cellulose, or plant fiber, and soy lecithin, an emulsifier often found in chocolate, peanut butter and protein bars, among other foods.

The materials were chosen for being recognized as safe, and for not containing any petroleum themselves. "When you have an oil spill, it's a horrible situation already. A lot of the current dispersants contain petroleum-based solvents, and common sense tells you that you don't want to add more petroleum materials," Kemp said.

Moreover, there have been concerns that some of the most widely used dispersants are more toxic than the oil itself. After the Deepwater Horizon spill in the Gulf of Mexico in 2010, BP sprayed the slick with 700,000 gallons of a chemical dispersant called Corexit. Marine toxicologist Susan Shaw said at the time that Corexit contains a chemical that causes internal bleeding and seemed to play a role in the elevated death levels of marine life in the Gulf of Mexico.

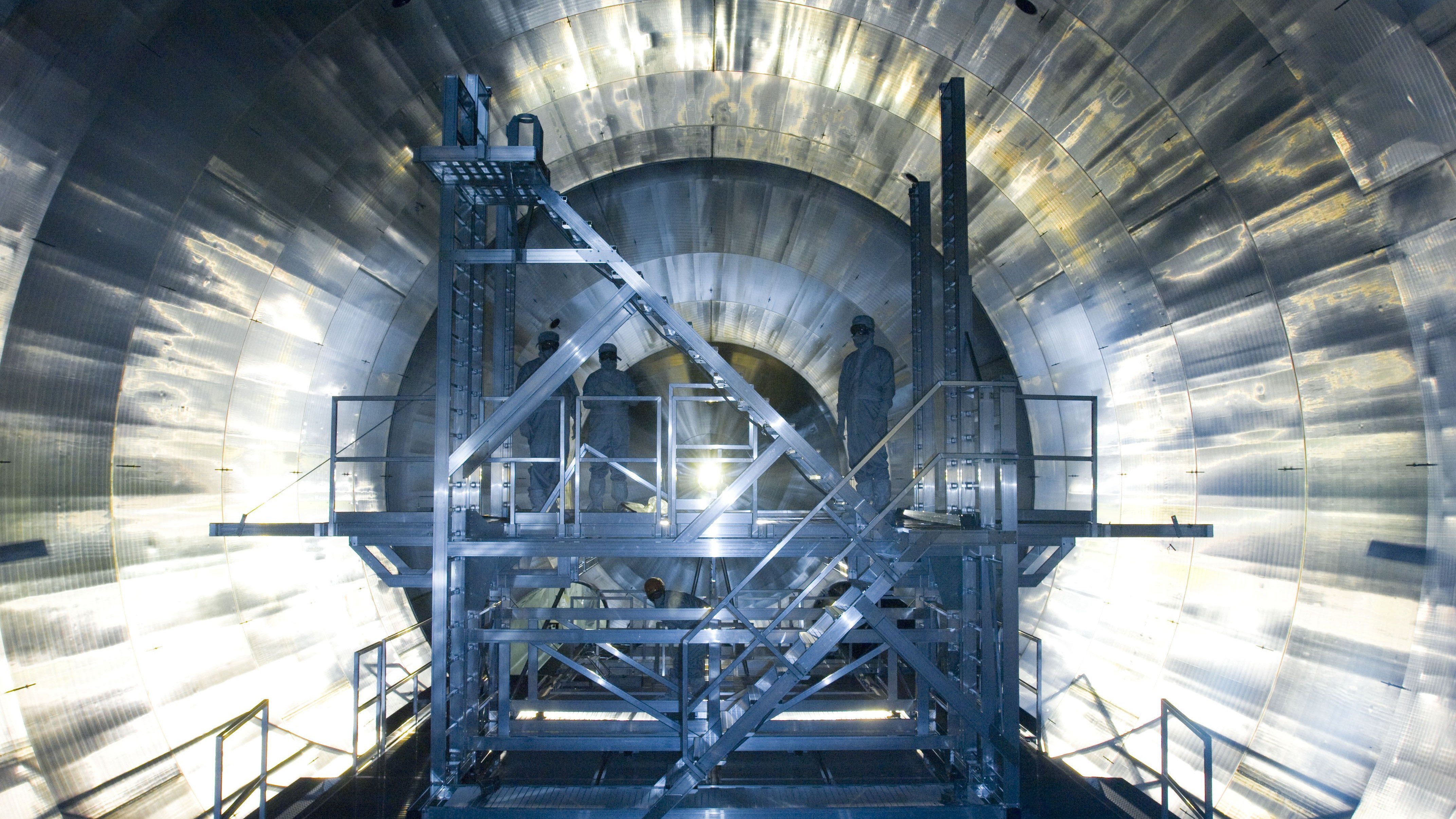

[Deepwater Horizon: Images of an Impact]

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

Despite their drawbacks, dispersants do play an important role in removing oil from the surface of an ocean or lake. By breaking up an oil slick into smaller particles, "in some cases, that improves microbial degradation," Kemp said. But current dispersants also move oil droplets from the surface into the water column. "So now plants and animal life that never would have come into contact with the slick have to deal with that … if you disperse the oil and put it through the food chain, while [removing the oil slick] seems like the right decision at the time, it isn't."

USM's new formulation floats while simultaneously breaking an oil slick into smaller droplets. With the oil at the surface, it could be skimmed off with booms or left to be degraded by bacteria. And the substance has nonstick properties. "When it comes into contact with a bird feather...it doesn't stick. You can rinse it off."

If USM can receive approval from the U.S. Environmental Protection Agency, the dispersant can quickly be manufactured in quantity. "When the team first worked on this issue," Kemp said, "they screened only the polymers available in ton quantities [that were] already commercial, already readily available. This has been designed to be economical. "

This story was provided by InnovationNewsDaily, a sister site to Live Science. You can follow InnovationNewsDaily Senior Writer Jeremy Hsu on Twitter @ScienceHsu. Follow InnovationNewsDaily on Twitter @News_Innovation, or on Facebook.

Rachel is a writer and editor based in Washington, D.C., who covers a range of topics for Live Science, from animals and global warming to technology and human behavior. Rachel also contributes to National Geographic News, Smithsonian Magazine and Scientific American, and she is currently a senior editor at Next City, a national urban affairs magazine. She has an English degree with a journalism concentration from Adelphi University in New York.