Unique Bacteria Fights Man-Made Chemical Mess

This Behind the Scenes article was provided to LiveScience in partnership with the National Science Foundation.

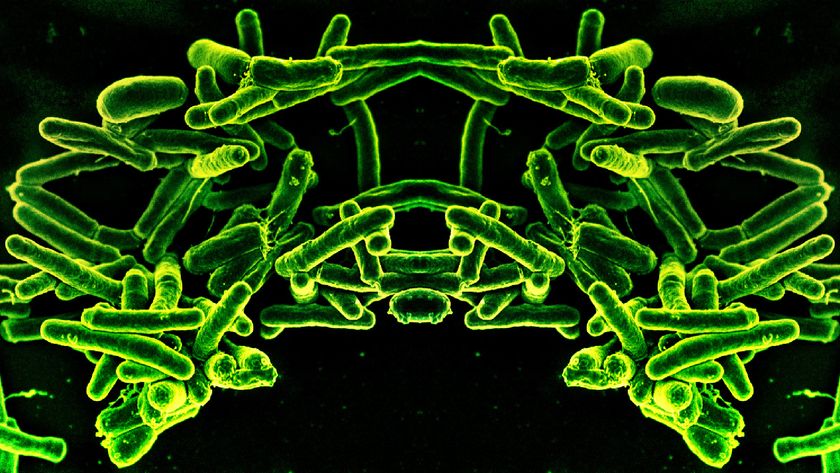

Researchers have developed a bacteria strain that is uniquely effective at degrading the toxic industrial chemicals known as PCBs, or polychlorinated biphenyls.

PCBs are toxic man-made organic chemicals that pose a threat to human health and to the environment.

The Environmental Protection Agency has classified PCBs as potential human carcinogens known to adversely affect the immune, reproductive, nervous and endocrine systems of humans and other animals. Used in U.S. industrial and commercial applications, PCBs were manufactured from 1929 until being banned in 1979. Because they are resistant to degradation, PCBs are still present in the environment.

Difficult to degrade

Cleaning up PCBs most often involves dredging PCB-laden soil and incinerating the soil or depositing it in a secure landfill. These remediation techniques are expensive. General Electric, for example, spent $561 million to dredge and pile 2.6 million cubic yards of Hudson River sediment contaminated with PCBs. Even after dredging, PCBs often remain embedded in surrounding rock.

The chlorine atoms in PCBs make these chemicals toxic and difficult to degrade. Even though there are naturally occurring PCB-degrading bacteria in the environment, they are slow to break down the chemical. Natural in situ dechlorination of highly chlorinated PCBs occurs under anaerobic conditions at the rate of approximately 5 percent per decade. This means that PCBs can persist in the environment for a very long time.

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

The Bioremediation Consulting Inc., with the support of the National Science Foundation Small Business Innovation Research Program, has been able to culture a robust PCB-degrading bacteria in large amounts, which could mitigate this public health problem.

The solution

Previously, researchers were unable to isolate these more robust bacteria because of their strong attachment to sediments.

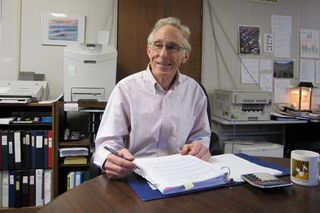

However, Margaret Findlay, BCI President and lead scientist, and Dr. Samuel Fogel, BCI Vice President and project scientist, were able to develop a culture — a member of the Dehalococcoides genus — which they've since made commercially available. The researchers were able to tease away the bacteria from a groundwater sample from a site in New Jersey. The team used common minerals, such as sodium chloride, ammonium chloride, phosphate and trace elements, to form the growth media.

The bacteria grown in the culture are not pathogenic, and should not cause adverse effects in the natural environment, according to the researchers' assessments. The cultured bacteria also do not change the pH of the water, leaving the concentration of the residual hydrochloric acid that the bacteria produce at a 1- or 2-parts-per-million level.

With the NSF SBIR grant, BCI produced large quantities of the bacteria to test its effectiveness in neutralizing PCBs by removing chlorine atoms.

BCI's culture showed its ability to degrade Aroclor 1260, a common commercial mixture of about 60 chemically similar PCBs containing 6 to 8 chlorines per molecule. Within 18 weeks, 44 percent of the PCBs with 6 to 8 chlorines were converted to PCBs that had 4 to 6 chlorines. Similar results were seen with another PCB mixture, Aroclor 1254.

BCI's breakthrough has the potential to be a cost-effective replacement of dredging and transporting soil to landfills.

How it works

The PCB-degrading bacteria reduce the number of chlorines in the biphenyl molecule. Then, as conditions become more oxygenated, common aerobic bacteria can further dechlorinate the molecule, as well as break the carbon rings that hold biphenyl molecules together.

"The important thing is to be able to knock off chlorines on the highly chlorinated PCBs . . . because some of them have dioxin properties that are particularly toxic," said Fogel. Once you are down to two, three or four chlorines, he said, aerobic bacteria can metabolize the biphenyls.

The dechlorination process using the PCB-degrading bacteria is quite complex. The mechanism involves PCB's role as an electron acceptor.

"PCBs are electron acceptors," said Fogel. "In order to have electrons flowing, you need an electron donor. Typically, [the donor] is a sugar molecule or a material like lactic acid that bacteria can ferment. One of the fermentation products is molecular hydrogen, and molecular hydrogen turns out to be the ultimate electron donor that these bacteria use to knock chlorines off."

The bacteria use H2 gas, produced by other naturally occurring soil bacteria, as an energy source, while fermenting sugar or fat. H2 acts as an electron donor to PCB. The bacteria's enzymes, dehalogenases, have an active site with vitamin B12, which becomes a strong reducing agent. The hydrogen gas helps reduce cobalt in the dehalogenases, which in turn, catalyzes the breaking of the chlorine bonds in PCB, replacing the chlorine atom with a hydrogen atom.

Once reductive dechlorination occurs — the process in which the PCB gained electrons — the bacteria leave a substrate that aerobic bacteria can attack. The aerobic bacteria break the PCB's aromatic rings, and the end product is mineralized carbon dioxide and hydrochloric acid.

Research History

Findlay, Fogel, and their team have been involved in studying Dehalococcoides-like bacteria since 1993. The researchers observed that with the bacteria present, reductive dechlorination occurred in anaerobic groundwater that was contaminated with trichloroethylene.

Companies came to BCI requesting evaluation of contaminated groundwater to see if reductive dechlorination of TCE was possible. For clients who already had the necessary bacteria present in their groundwater, BCI could enhance the impact of the bacteria by adding the right electron donor and establishing optimal biochemical conditions. However, there were clients whose groundwater did not harbor the bacteria, so bacteria-initiated dechlorination did not occur.

BCI researchers solved this problem by growing Dehalococcoides under anaerobic conditions in a mineral salt media and supplying the bacteria commercially to clients whose groundwater lacked the organism.

The researchers soon realized that there was a Dehalococcoides strain able to dechlorinate aromatic compounds such as trichlorobenzenes.

Routine testing of groundwater containing TCB, TCE, and PCB led BCI researchers to believe that Dehalococcoides could dechlorinate PCBs in non-laboratory conditions, at real-world contaminated sites. Academic literature, especially that of S. H. Zinder and J. M. Gossett at Cornell University, and L. Adrian at Technische Universitat, Berlin, which demonstrated Dehalococcoides' limited ability to dechlorinate PCB, also supported this belief.

The researchers also knew that there were different strains of Dehalococcoides — the same genus and species, but different varieties.

"We became convinced from all the literature that Dehalococcoides would become the important organism to deal with, what we consider, the last frontier of bioremediation," said Fogel. "That is, PCBs are the final frontier, in the sense that, there is no other group of chlorinated compounds — or for that matter any chemical — that is more difficult to biodegrade than PCBs."

With a grant from the Electric Power Research Institute, BCI researchers tested client-supplied ground-water samples containing TCB, PCB, TCE, and Dehalococcoides to assess whether the strain of bacteria from these samples would be well suited to biodegrade the groundwater PCB. The bacteria efficiently removed chlorines.

With this success, BCI researchers shifted attention to growing a culture of this PCB-degrading organism.

Now, BCI can offer cultures of bacteria to treat PCB-contaminated groundwater or soil. The bacteria are expected to carry out reductive dechlorination both ex situ and in situ, which can potentially eliminate the need to dredge PCB-polluted soil.

BCI researchers are informing the public and the remediation community about their breakthrough, and pursuing new ways to tailor the engineering application of this finding.

BCI researchers have had a long journey with PCB, because they want to improve the environment.

"If you drive along the Hudson River today, you will see mounds of sediment . . . dredged from the bottom," said Fogel. But, ". . . perhaps [we] should use biological methods [to remediate them] . . . Here at BCI, we are environmental scientists who want to make a change, so we go through all the necessary steps."

Editor's Note: The researchers depicted in Behind the Scenes articles have been supported by the National Science Foundation, the federal agency charged with funding basic research and education across all fields of science and engineering. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author and do not necessarily reflect the views of the National Science Foundation. See the Behind the Scenes Archive.