Bone Replacements and Heart Monitors Spur Health Revolution in Open Source 3D Printing (Op-Ed)

This article was originally published at The Conversation. The publication contributed the article to Live Science's Expert Voices: Op-Ed & Insights.

The evolution of 3D printing has moved quickly and it is now poised to alter every aspect of our lives and health. Thousands of Europeans are enjoying 3D-printed metal orthopaedic implants to support or replace missing bones and, in the US, thousands more have benefited from 3D printing used by dentists. Most people that need hearing aids have custom 3D-printed devices comfortably resting in their ears now.

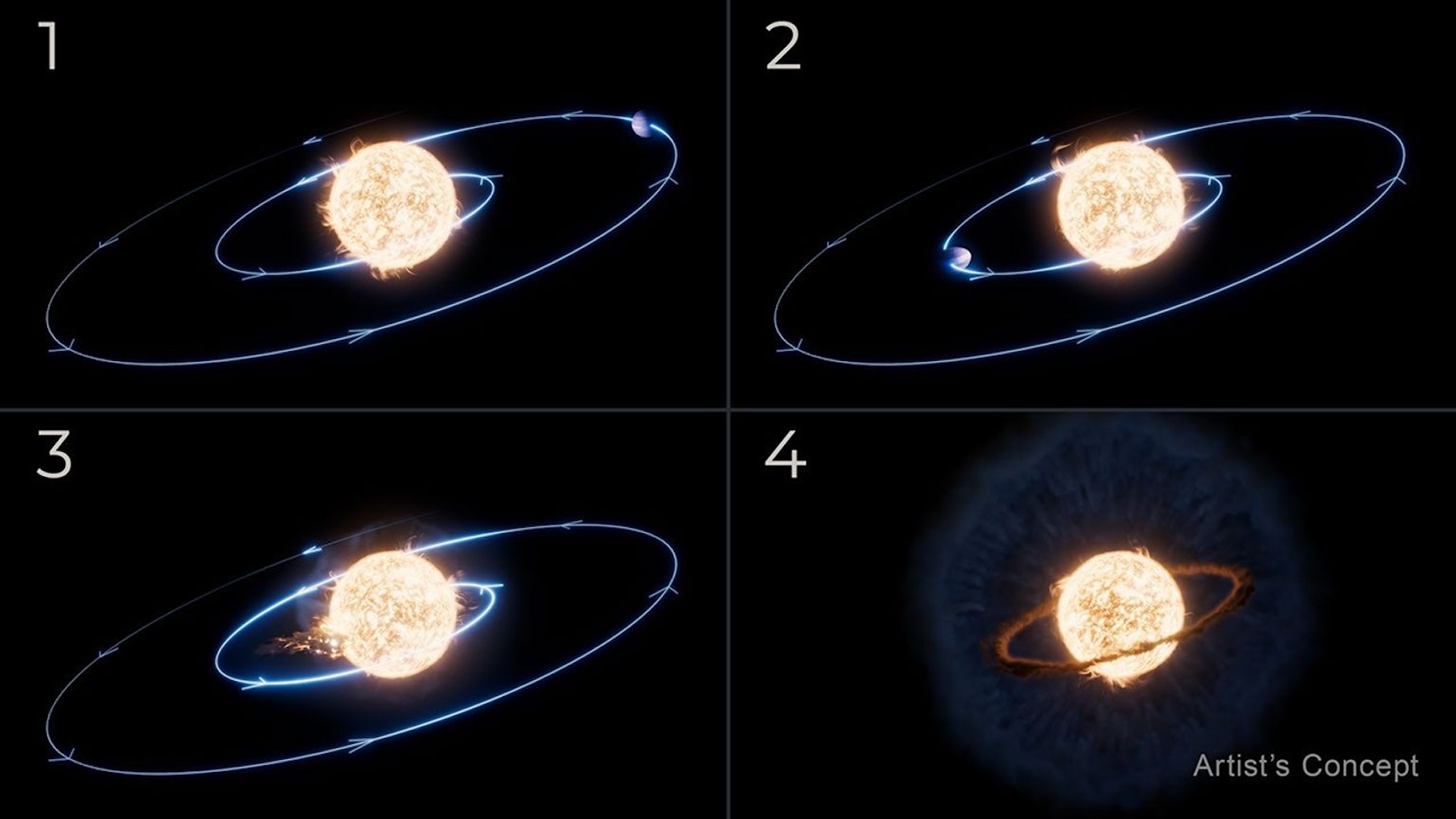

It is hard not to get excited about the latest 3D-printed marvels in the world’s labs such as the 3D-printed “heart jacket”, which was successfully used to monitor a heart of a rabbit. Scientists used a sensor-studded silicone sheath to gauge things like contractions, temperatures and acid levels across the surface of the rabbit’s heart. With a little more time and effort, there is potential for a human implant.

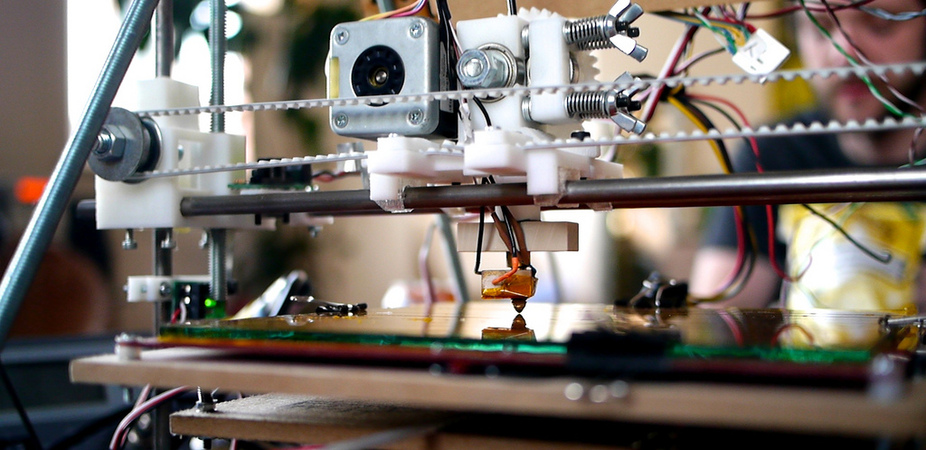

The 3D printers used for orthopaedic implants, hearing aids and heart monitors are all high-end, made by expensive manufacturing tools far removed from the consumer printers that have captured public imagination. Low-cost consumer 3D printers are generally also limited to printing in plastic, but there are a surprising number of uses for such a relatively simple tool.

Print your own design

Imagine you hurt your ankle and your doctor recommends physical therapy with a “wobble board” to improve balance and strengthen your ankle joint. These are not overly common items and you could probably buy one on the internet for more than US$100 and wait for it to arrive in the mail. But if you own a 3D printer you now have another option: you can customise a wobble board using an open source design, print it on your 3D printer and bolt it to a circle of plywood for well under $5.

There are dozens of other open designs for health aids on the internet – from simple splints to complex prosthetic hands. What they all share in common is they are radically less expensive than the products on the market.

The extreme economic savings that can be had from using a personal 3D printer hasn’t escaped the notice of those of us who work in the sciences. Similar to the excessive mark-ups for anything related to healthcare, scientists also often suffer from shockingly expensive scientific equipment prices. 3D printers offer us a solution too.

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

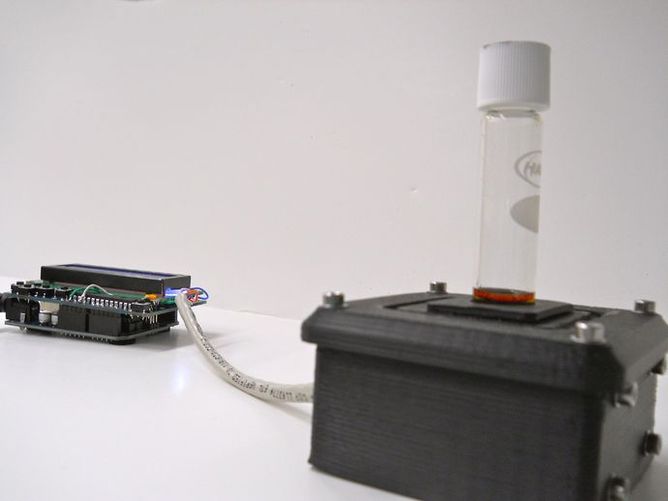

Consider the colourimeter, a simple device used to detect colour in a wide range of science applications including testing water. A colourimeter is used for the chemical oxygen demand (COD) to detect contamination of drinking water. High-quality colourimeters cost over $2000. My research group developed an open source 3D-printable colourimeter that costs $50 and after testing hundreds of samples we showed it is equivalent in quality to the market version. That is a factor of 40 savings on a 3D printable that is actually more flexible than the original.

Market-bought colourimeters are all made for a specific size of cuvette or test tube, which are also always specific to the fluid holders that each company sells. Our device can easily be customised and adapted to any size of fluid holder from any company. Simply print out the new version and slide it into the device for a few more cents of plastic.

Next, we were looking for an inexpensive and accurate way to measure the turbidity (or cloudiness) of drinking water in the developing world. Nephalometers, which are used to measure turbidity again cost over $2,000 – which is not an option for widespread testing for the more than billion people that suffer from extreme poverty and lack of access to safe drinking water. So we made the colorimeter portable and added another LED and sensor so we now have a nephalometer plus colourimeter device with lab-grade accuracy for under $100.

Hack and develop

Now our device can be used by anyone to make the next even more sophisticated device. Our colourimeter uses an Arduino, which is an open source micro-controller that enables anyone with an interest to easily hack it and use it for their own projects. We developed the open source nephalometer+colourimeter easily and quickly, because others had already developed the sensor and basic software coupled to the Arduino. This is the power of open source. Just like the incredible rate of innovation witnessed in open source software, the concept of open source design for 3D-printable hardware is catching on like wildfire. Hundreds of open source 3D-printable science and health tools have already been developed.

This is all just the beginning. Fully open source 3D printable labs are coming. They will help scientists stretch their funding to do more and better research, which will lead to faster discoveries and an accelerated rate of technological development. All of which will hopefully enable all of us, wherever we are in the world, to live richer and healthier lives.

Joshua M. Pearce's receives funding from organisations listed here: http://bit.ly/1kfxbvk

This article was originally published on The Conversation. Read the original article. The views expressed are those of the author and do not necessarily reflect the views of the publisher. This version of the article was originally published on Live Science.