Explainer: What is Electronic Skin?

This article was originally published at The Conversation. The publication contributed the article to Live Science's Expert Voices: Op-Ed & Insights.

Once a topic explored exclusively in science fiction, the notion of restoring sensory feelings to humans and to machines is now approaching reality. Scientists around the world are developing artificial organs such as bionic eyes that could potentially restore sensory feelings to the disabled or provide useful sensory capabilities to machines. Now electronic skin is being developed in an attempt to bring a sense of touch to robots and those who wear prosthetics. If the field advances even further, it could even be used in wearable technology.

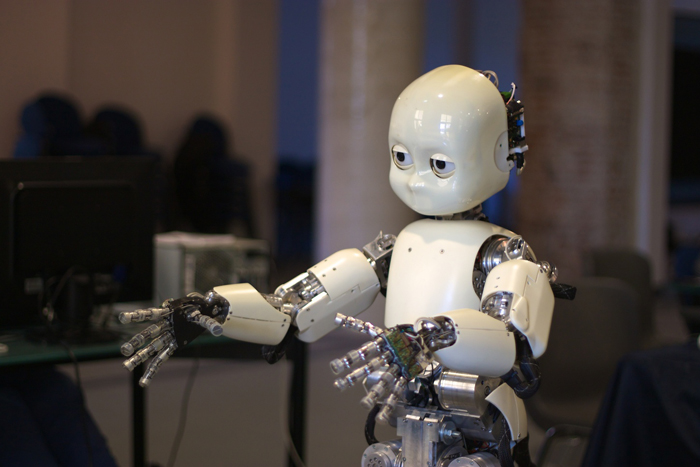

As robots become part of our daily lives, electronic skin will be vital. If your robot is going to help you around the house or with medical care, tactile sensing will be a fundamental part of its safe operation. It needs to be able to detect when a surface is slippery as well as sense the shape, texture and temperature of the objects it grasps. If it can sense the properties of that object, the robot can also decide how much force it should apply when it holds it.

It is the use of distributed sensors to measure subtle pressure changes that has attracted the attention of wearable technology makers and enthusiasts. Artificial electronic skin, or E-skin has the potential to be used for on-body health monitoring and minimally invasive surgery as well as in robotics and prosthetics.

Soft, bendable, stretchy

A big breakthrough for electronic skin will come when it can be made soft and bendable like human skin. Soft and comfortable electronic skin would make for a superior ability to handle objects and eliminate much of the inconvenience and discomfort associated with current alternatives. It would also mark a significant step towards its use in wearable technology.

But this is a challenge. For the skin to conform to curved surfaces, the electronics need to be bendable and microelectronics technology is at present, essentially flat.

A variety of approaches and designs are being pursued to overcome this problem though. Early attempts to obtain bendable electronic skin followed the flexible printed circuit board route. Here, off-the-shelf sensing and electronic components are soldered to bendable printed circuit boards. These solutions are akin to having mechanically integrated but otherwise distinct and stiff sub-circuit islands of off-the-shelf electronic components, connected to one another by metal interconnects.

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

The approach has been successfully used in ROBOSKIN, during which we developed tactile skin for various robots including the iCub humanoid robot developed at IIT in Italy.

The semi-rigid skin we produced is one of the most functional ways to cover body parts with large curvatures, such as arms of iCub. It serves some of the most pressing needs in robotics for the time being but soon we’ll need something superior to that made possible today with off-the-shelf components.

An interesting development in this direction is electronic skin that uses organic semiconductor-based thin film transistors, which has been developed at the University of Tokyo and Stanford University. The organic semiconductors have inherent bendability because of their particular molecular structures, which goes some way to solving the softness problem.

On the downside, transistors and sensors are slow when used with these materials because of the low charge carrier mobility. It takes electrons longer to move within these materials than in others. They are also less stable.

To effectively use electronic skin in robotics or elsewhere, we need sensory data to be acquired and transmitted in less than a millisecond so that the robot can react quickly. That means that high-mobility materials like single-crystal silicon are a better option. At the University of Glasgow, we’re developing electronic skin using silicon and other high-mobility materials that can be processed using micro/nanofabrication tools.

But this takes us back to the flexibility problem because silicon cracks on bending. We have overcome these challenges by using a transfer-printing approach. We carve silicon nanowires out of bulk wafers and transfer print them onto flexible plastic substrates. The skin itself is a rubbery polymer called polyimide that has tiny silicon nanowires on it, which lead to thin-film transistors and sensors.

Flexible, human like skin will be particularly important in our attempts to improve prosthetics – a field that is already, in many ways very advanced. Using what’s called myoelectric linking, a prosthetic limb can pick up electrical impulses from remaining muscle fibres on the arm or leg, transmitting those impulses to articulating fingers and a thumb.

But even though prosthetic limbs are continually being upgraded and remodelled to look and function as close to a real limb as possible, they still lack the characteristics of human skin because they are much stiffer. Eventually, these advanced prosthetic devices will be expected to touch and be touched by other people.

This goal is closer than ever with the sensitive synthetic skin being developed at the University of Glasgow. This printable tactile skin could lead to next-generation prosthetic arms that would enable users to feel a light touch, shake hands, and type naturally because the arm will send signals to the brain and in turn respond to brain signals.

Once these hurdles are overcome, we can further improve the experience of using electronic skin using smaller and more efficient batteries and lifelike materials that will more closely resemble real skin. It’s an exciting era for the field, with lots of developments on the horizon.

Ravinder Dahiya works for the University of Glasgow, UK. He receives funding from Engineering and Physical Sciences Research Council, The Royal Society and the European Commission.

This article was originally published on The Conversation. Read the original article. Follow all of the Expert Voices issues and debates — and become part of the discussion — on Facebook, Twitter and Google +. The views expressed are those of the author and do not necessarily reflect the views of the publisher. This version of the article was originally published on Live Science.