New Biomaterial Mimics Functionality of Natural Cartilage

This Research in Action article was provided to Live Science in partnership with the National Science Foundation.

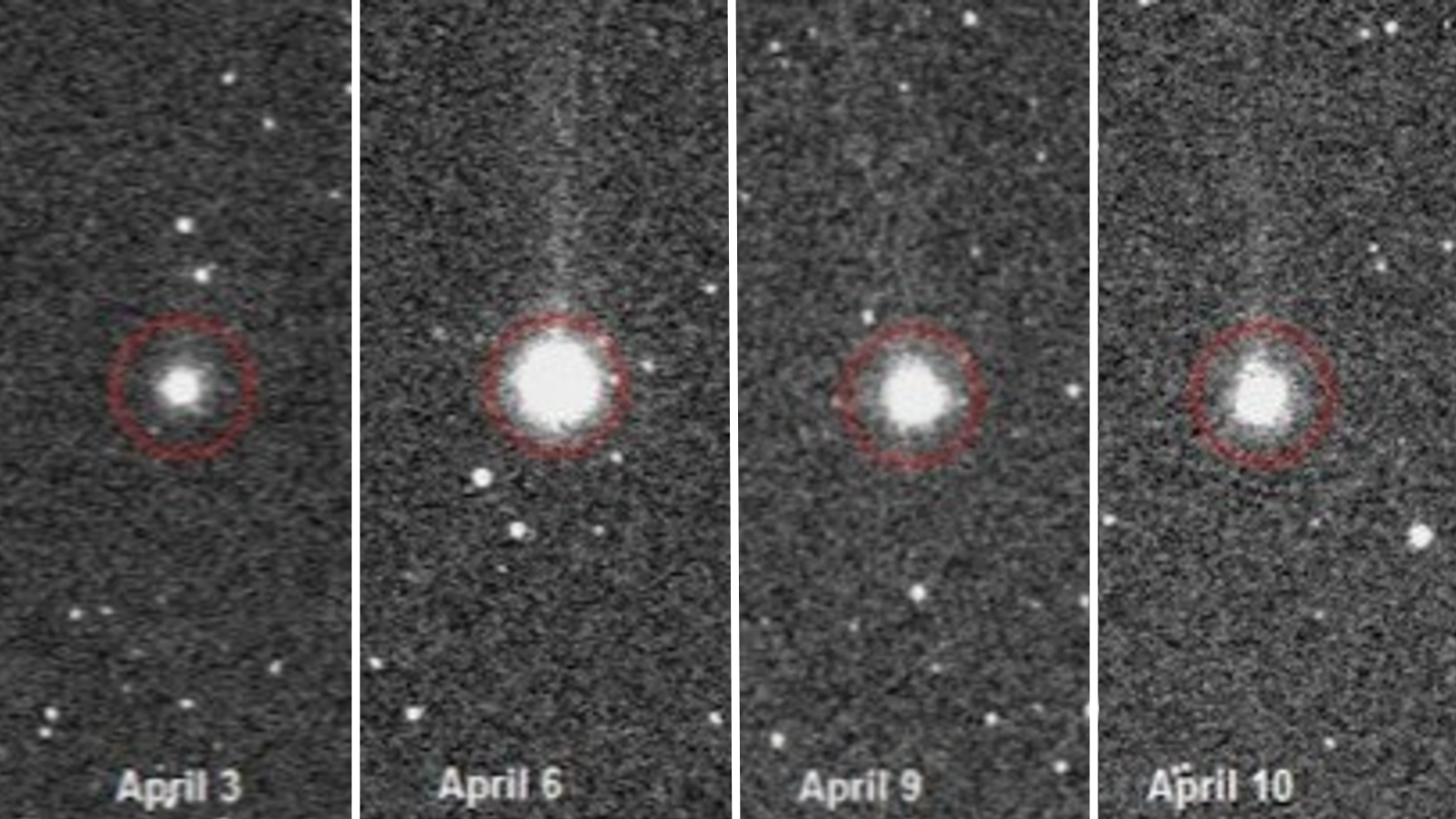

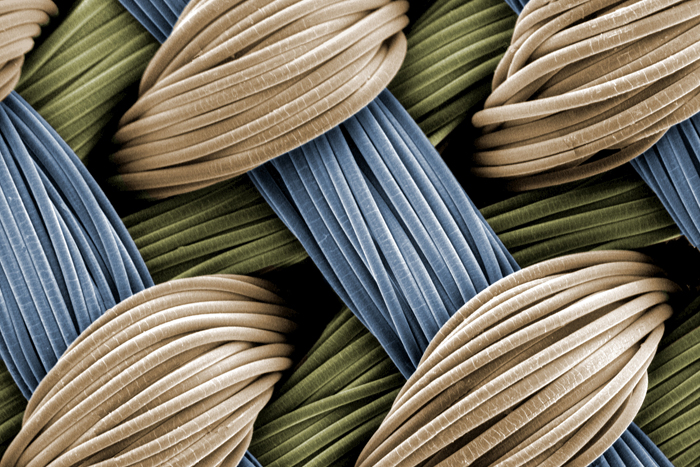

These tiny woven fibers make up a scaffold that is part of a framework for growing cartilage.

Each of the scaffold’s seven layers is about as thick as a human hair, with the finished product about 1 millimeter thick.

Humans and animals suffering from deteriorated articular cartilage — tissue that cushions bone joints — may one day find relief from the new synthetic material that mimics the suppleness and strength of natural cartilage tissue.

Articular cartilage is a durable, load-bearing tissue. Although it can withstand great stress while remaining lubricated enough to support thousands of joint movements, it wears away with overuse, injury or disease. Unfortunately, the uniqueness of this remarkable organic substance makes it difficult to replace.

Nevertheless, Duke University engineers Farshid Guilak and Xuanhe Zhao developed a flexible, durable tissue that can model the functionality of natural cartilage They created the synthetic tissue by uniting a 3-D fabric scaffold that Guilak and his team developed in 2007 with a hydrogel that Zhao and a team from Harvard University engineered in 2012. Hydrogels are composed of many molecule chains, called polymers, suspended in water. Just as a steel framework may provide stability for concrete poured over it, the 3-D fabric creates a lattice scaffold that provides stability for the malleable hydrogel.

Zhao’s resilient, lubricating hydrogel integrates with the durable fabric, resulting in a synthetic material that may be injected with stem cells and grown into articular cartilage tissue.

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

While this new artificial tissue does not serve as an exact replica of natural articular cartilage, it is a highly advanced synthetic material. The technology proves that a functional biomaterial simulating the pliable support of joint cartilage can be produced in the laboratory. "From a mechanical standpoint, this technology remedies the issues that other types of synthetic cartilage have had," says Zhao. "It is a very promising candidate for artificial cartilage in the future."

The National Science Foundation supported the Triangle Center of Excellence for Materials Research and Innovation involvement in this collaborative project, as well as the development of Zhao’s lubricating hydrogel in 2012. The research was described in the December 17, 2013 issue of the journal Advanced Functional Materials.

Editor's Note: Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author and do not necessarily reflect the views of the National Science Foundation. See the Research in Action archive.