This article was originally published on The Conversation. The publication contributed this article to Live Science's Expert Voices: Op-Ed & Insights.

Metals are one of the most-used materials in the modern built world, found in everything from buildings to aircraft to smartphones. While most metals are mined from the earth, scientists have recently created a new generation of metals in the lab. These so-called bulk metallic glasses have unique properties. They’re stronger and harder than conventional metals, but can be formed like plastics. This sounds astonishing. What’s behind their special characteristics?

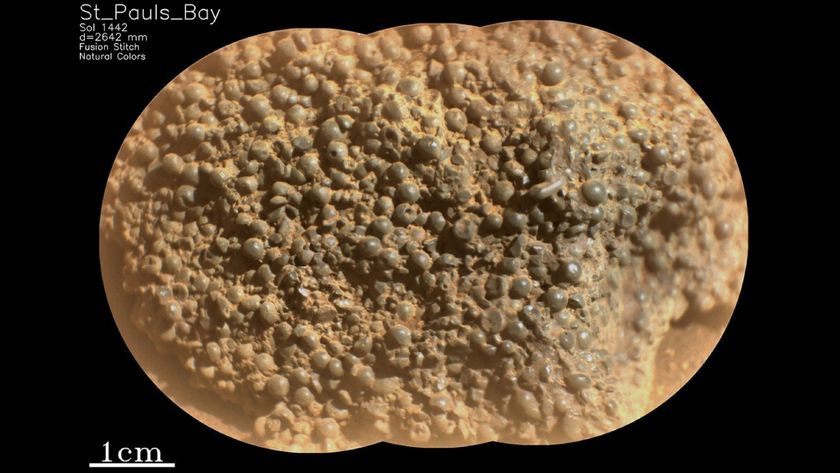

To the naked eye, these lab-made materials look like regular metals, but are smoother and very shiny. The secret behind their unusual properties has to do with their structure on an atomic level. My colleagues (at UdS and OSU) and I undertook new research using high-energy X-ray light to unravel some of their mysteries. We have identified the relationship between bulk metallic glasses' atomic-scale structure and their visible-scale viscous flow – essentially what allows them to flow like thick honey or thin water.

Super strong and can also flow

Bulk metallic glasses are made of multiple components, including zirconium, copper, nickel, aluminum, gold and platinum. They exhibit very high strength. If you tear, bend or press a piece of one of these metals, it is so strong that deforming it permanently is very difficult. It can store much more deformation energy than any other metals, making it an ideal spring material.

But what makes bulk metallic glasses unique is that their great strength is combined with the ability to flow like a thick liquid when in a special supercooled liquid state that regular metals cannot reach. When heated to a certain temperature range, they flow like viscous liquid. This makes it possible to mold these special metals by hot-forming processing typically used for traditional glasses and plastics. In principle, you can even blow the metals as you would with bottle glasses.

All metals in nature have a regular, repeating arrangement of atoms, where atoms are stacked up almost uniformly in a three-dimensional lattice. In contrast, these lab-made bulk metallic glasses have a more or less random atomic arrangement. This is because they are made by cooling heated liquid material so fast that atoms are “frozen-in” at their current positions; it maintains the amorphous structure of a liquid.

Normal metals suffer from certain defects that widely exist in their regular, crystalline structure. When a force is applied, those defects help the planes of organized atoms slip past each other; thus, these alloys can fairly easily be permanently deformed. This does not happen in bulk metallic glasses since their atoms are all mixed up, not organized in an orderly grid. Their structure means they can resist much larger deformation or force until their shape is permanently changed.

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

But what’s really unusual about bulk metallic glasses is their ability to flow like a thick liquid in their supercooled liquid state – a unique state they can stay in quite stably, while almost impossible for conventional metals to reach. To get a bulk metallic glass into this unusual state, you heat it to a certain temperature range – usually a bit more than two-thirds of the way to its melting point – the so-called supercooled liquid region. The rising temperature unfreezes the atoms so they can move around. They behave like a liquid, but a very thick, slow-flowing one. Making use of this special viscous flow region, scientists are able to form and shape the geometries of bulk metallic glasses into complex shapes by, for example, “blow molding,“ something other modes of metal processing cannot manage.

Luxury watchmakers love the strength and moldability of these materials.

It’s these special properties that make bulk metallic glasses so appealing for consumer electronics applications. Back in 2010, the technology giant Apple reached an exclusive agreement with Liquidmetal Technologies for using bulk metallic glasses in their products, and Apple itself keeps filing patents on the new material. Luxury watchmaker Swatch Group has already used the unusual metals in their top-end brand Omega. These manufacturers value their strength and being able to mold them into precise complex shapes for small components.

Strap on the X-ray specs

It’s been a big puzzle why bulk metallic glasses can be viscous. And what makes some compositions more viscous than others? To investigate, we used an extremely intense X-ray light source to look at the materials on a nanometer scale – a billionth of a meter. We wanted to observe how the atoms arrange themselves.

We used the particle accelerator PETRA III at DESY, the world’s most brilliant radiation source, to generate the light. The X-ray beam is not only billions of times brighter than what’s used in hospitals, universities or industrial laboratories, but also extremely tightly focused with a very short wavelength. Such a light can detect even tiny changes in atomic positions. The detection process is fast enough that we can monitor the structural changes every one second and as we raise the temperature degree by degree.

My colleagues and I found that the atomic arrangement in bulk metallic glass-forming liquids shows much order within about one nanometer. With increasing temperature, the structure at some distances expands much faster than at others, and does so in an inconsistent way. More interestingly, atoms at certain distances are more “important” than others, because they are key players in determining the ability of viscous flow.

We pinpointed the key distance to be equivalent to about three to four atomic diameters. If atoms in one bulk metallic glass arrange themselves in such a way that the local volume around those atoms at the key distance expands faster with rising temperature than in another bulk metallic glass, its supercooled liquid is much “thinner” or easier to flow than that of the other.

This shows the origin of the viscous flow ability in atomic-scale structure and explains what atomic arrangement can make one composition more viscous than another. The slower the atoms develop their particular complex order at that crucial three to four atomic diameters distance, the more viscous the material is. With this knowledge of structure, it becomes possible to predict viscosity by knowing the atomic arrangement of a bulk metallic glass and simulating the movement of atoms by computer – before making it in a laboratory.

Our finding suggests how in the future we might tailor desired properties by engineering atomic-scale structures in this new generation of metals.

Shuai Wei is Feodor Lynen Postdoctoral Research Fellow in Chemistry & Biochemistry Dept. at Arizona State University.

This article was originally published on The Conversation. Read the original article. Follow all of the Expert Voices issues and debates — and become part of the discussion — on Facebook, Twitter and Google +. The views expressed are those of the author and do not necessarily reflect the views of the publisher. This version of the article was originally published on Live Science.