Open-Source Prototype Turns Any Room Into a 3D Printer

Spring cleaning tip from Sweden: If you're wondering what do to with that extra space in the garage or den, why not turn the room into a giant 3D printer?

That's the Swedes for you — always thinking.

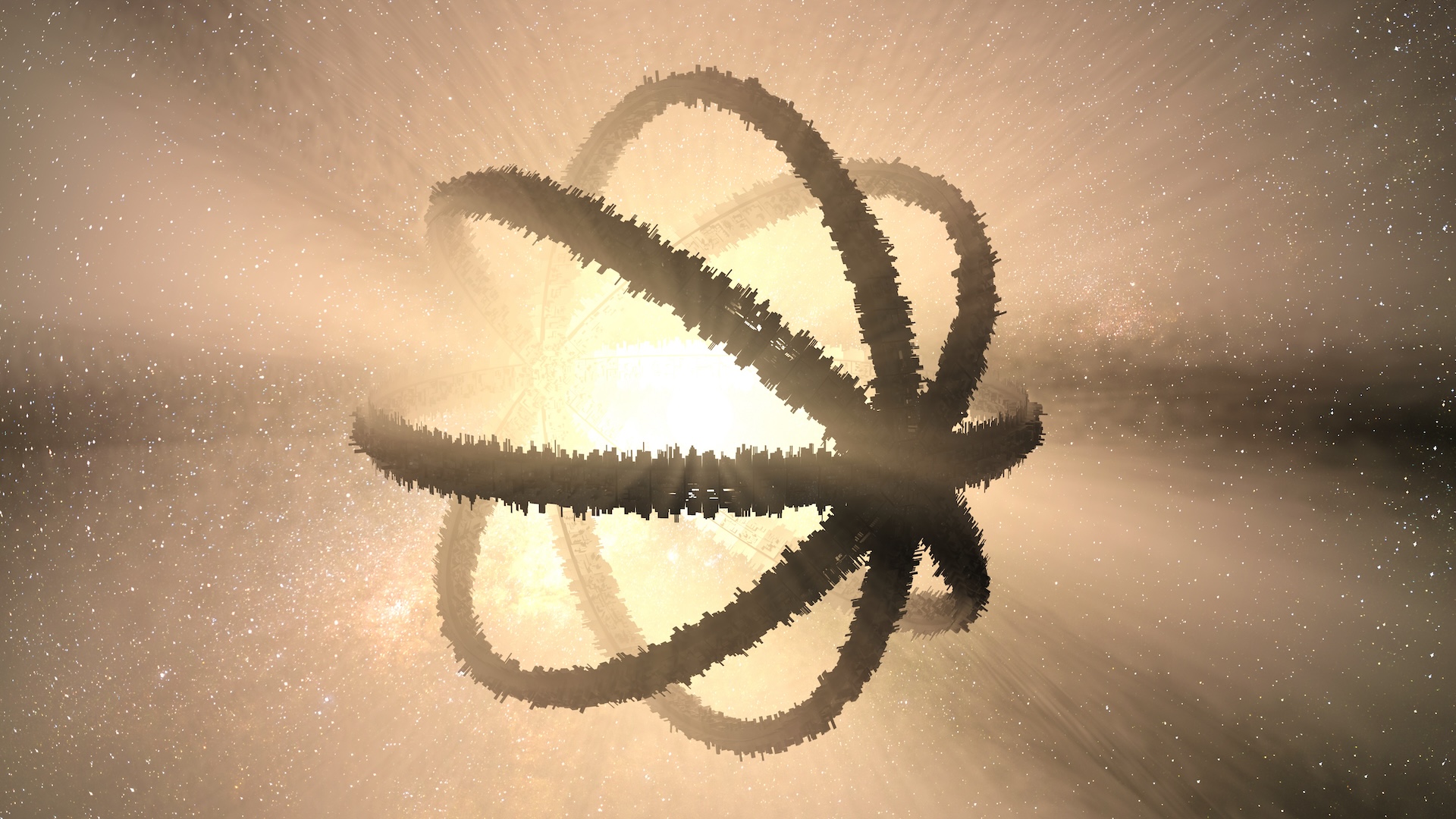

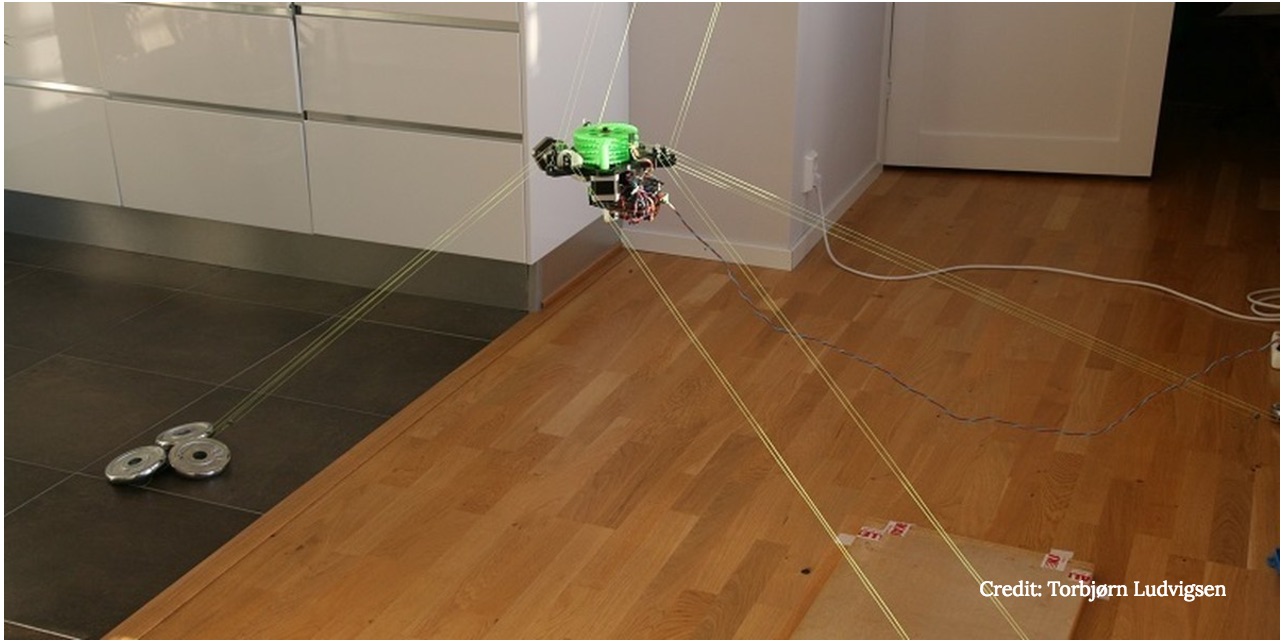

Swedish inventor Torbjørn Ludvigsen has spent the last three years developing a new kind of large-format 3D printer that can build furniture-sized objects in any room — surprisingly easily and relatively cheaply. Ludvigsen's invention, the Hangprinter, employs a system of wires and computer-controlled pulleys anchored to the walls, floor, and ceiling. Once installed, the Hangprinter essentially uses the room itself as a casing.

The Hangprinter isn't the first large-format, caseless 3D-printing system, but it is unique in several ways. For one thing, it's cheap. All the hardware and firmware components can be purchased for about $250. Also, the design is open source, meaning that anyone can download the instructions and add improvements — or incorporate upgrades designed by other makers. Finally, the Hangprinter is designed to self-replicate. Most of the component parts needed to make a Hangprinter can be printed out by the Hangprinter itself.

It all adds up to a system that, Ludvigsen hopes, will nudge the power and potential of 3D printing away from large corporations and back to the people. Ludvigsen said via email that the Hangprinter is an experiment in sociology as well as technology.

"Specifically, I want 3D printing to avoid the fate of the 2D-printing business, where machines are programmed to self destruct after a certain amount of prints," he said. "My best bet to avoid this is to go for not only open source, but self-replication by design. Hangprinter is designed to manufacture a large fraction of its own parts and to be easy to build, copy, and make money from."

The Hangprinter project is part of a larger initiative in the maker community known as RepRap, which stands for Replicating Rapid Prototyper. The idea is to disseminate 3D-printing technology to low- and medium-income communities by way of open-source design and self-replicating machines.

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

"In addition to avoiding self-destructing machines, open source machinery may also distribute wealth and power towards median families like the one I grew up in," Ludvigsen said.

This is no idle notion for Ludvigsen. A physics student at Umeå University in Sweden, he recently wrote his master's thesis on the topic.

In a demo video, Ludvigsen shows time-lapse video of the Hangprinter making a relatively simple and functional object — a lampshade.

The Hangmaker has also been cut loose on more artistic projects. Ludvigsen recently used the system to assemble a five-foot sculpture of the Tower of Babel.

As materials and resolution improve, Ludvigsen hopes the Hangprinter will become versatile enough to print out furniture, tools, and possibly fully functional additional machines with moving parts of their own. He's also hoping to raise money via crowdfunding to continue research and development.

While the current prototype version of the Hangprinter is fully operational, there's plenty of room for improvement, Ludvigsen said. In fact, improvement is another reason why he's chosen to distribute the design for free.

"This is a flexible manufacturing technique, so it will be useful in lots of different situations that I can not foresee," he said. "Some of them might be very important/cool/useful. I wouldn't want to stand in the way of important, cool, and useful things happening."

RELATED: This Is the First Privately Commissioned 3D-Printed Object Made in Space

Originally published on Seeker.