Self-Replicating 3D Printers Could Build Moon Bases, Fight Global Warming

A 3D printer that could re-create itself from lunar material is in development at a university in Canada.

The technology could one day enable humans to 3D-print lunar bases, as well as conduct in-space manufacturing of satellites and solar shields on the moon that could help fight global warming, according to Alex Ellery, an associate professor in the Department of Mechanical and Aerospace Engineering at Carleton University in Ottawa, who is leading the project.

"I believe that self-replicating machines will be transformative for space exploration because it effectively bypasses launch costs," Ellery told Space.com. [How Moon Bases and Lunar Colonies Work (Infographic)]

The engineer envisions a single 3D printer could be delivered to the moon, where it would make thousands of its copies from surrounding lunar material. Once there would be enough 3D printers, the self-replicating factory would focus on building all other equipment and infrastructure needed for human exploration.

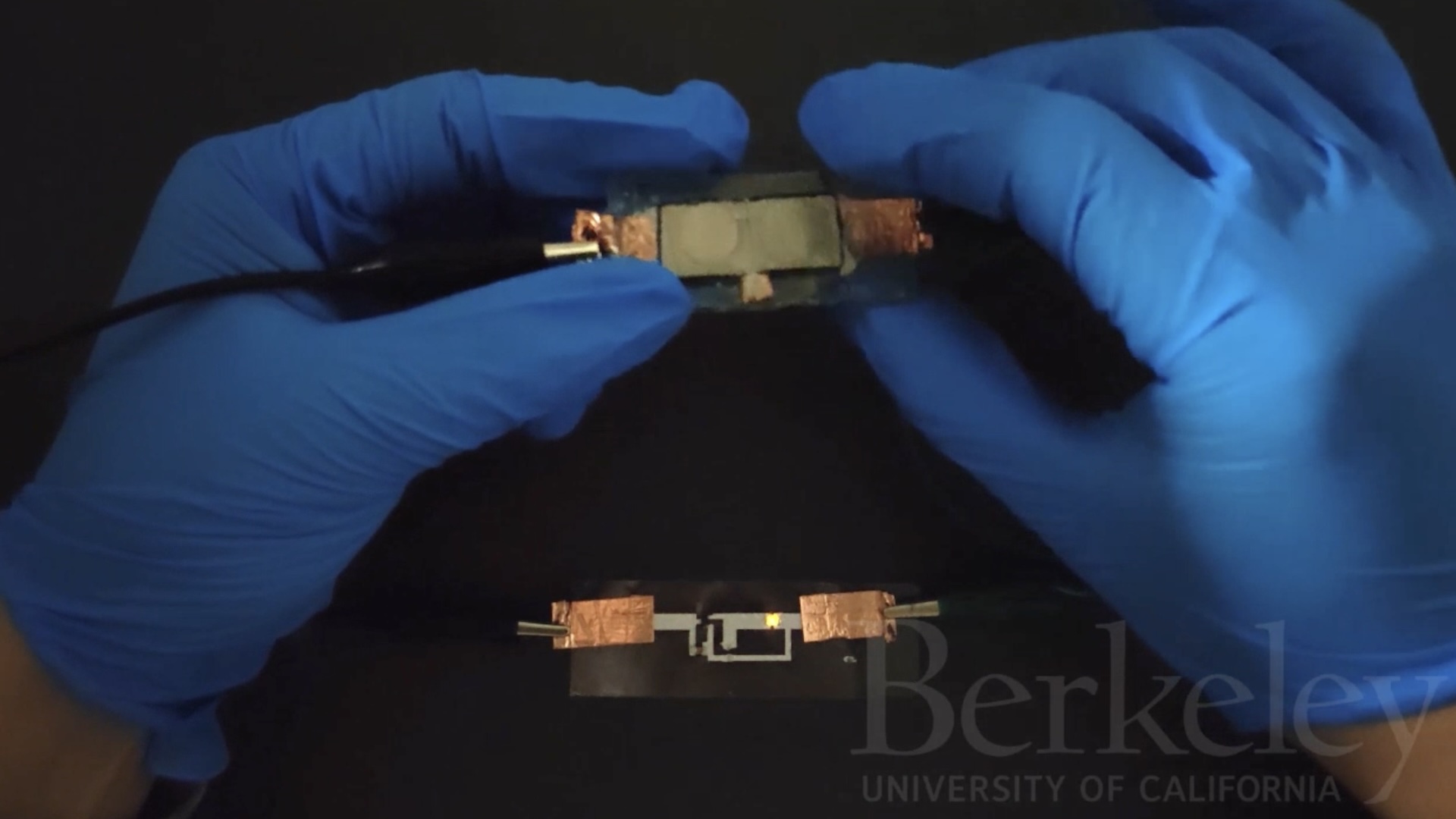

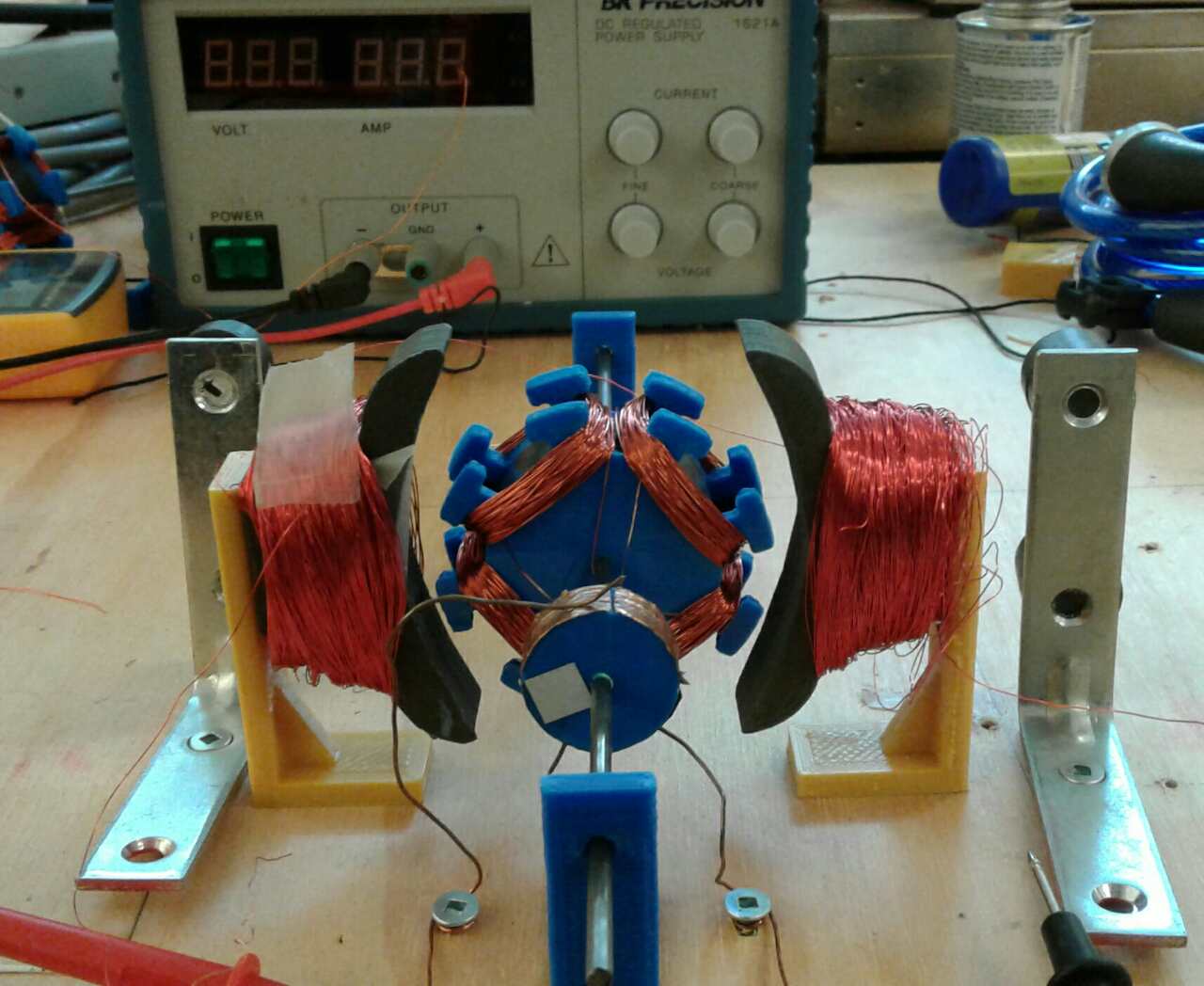

Ellery said he and his colleagues are close to being able to 3D-print a fully functioning electric motor from material similar to what can be sourced on the moon. Although some commercially available 3D printers can reprint some of their own parts, none of those printers can produce motors and electronics, according to Ellery.

"Our starting point is the RepRap 3D printer, which can print many of its own plastic parts," Ellery told Space.com, referring to the open-source device originally developed by the University of Bath in the United Kingdom. "In order to fully self-replicate itself, it needs to print its metal bars, its electric motors, its electronics and software, and self-assemble."

Ellery and his team, who described the project in an article published in the Journal of Spacecraft and Rockets last year, are using a mixture of a plastic material and iron filings to 3D-print two parts of the motor, the stator and the rotor.

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

"We need to maximize magnetic threading through the rotor, which requires more iron, but minimize eddy currents in the stator, which requires less iron," Ellery said. "So we have been varying the amount of iron in the plastic matrix."

Ellery said that elements needed for creating a similar mixture could be extracted from the lunar regolith. The lunar 3D-printer, fitted with a robotic arm, would scoop up the regolith and heat it to about 1,650 degrees Fahrenheit (900 degrees Celsius) using a so-called frensel lens to focus sunlight into a beam. The process would first remove volatile gases from the lunar soil. Subsequently, a component called ilmenite would be separated and used for extraction of iron, according to Ellery.

"Although we are using [polylactic acid] plastic [to 3D-print components], I envisage replacing this with silicone plastic — this can be manufactured from lunar volatile carbon compounds and lunar water," Ellery explained.

As a next step toward 3D-printing the motor, the researchers are aiming to replace the motor's wire coils with aluminum coils printed onto a polylactic acid plastic substrate (the latter is a common material used for 3D printing). On the moon, the aluminum would be replaced with fernico (iron-nickel-cobalt alloy) and the plastic would be replaced with a ceramic substrate made from melted lunar soil.

The magnetic field produced by the aluminum coils printed on the plastic substrate is "actually quite weak, so we are trying figure out ways to add more layers to increase the amount of current that goes through them," Ellery said. "But eventually, what we will do is that we will integrate that into the motor so that will give us a complete core, which is 3D-printed."

Ellery believes that he will have a fully functioning 3D-printed motor in a few months. The other prerequisite for a fully self-replicating machine — the electronics — is a problem that will probably take much longer to solve, he said.

This small motor was made using some 3D-printed parts. Researchers at Carleton University are working to make the entire motor 3D-printable. Credit: Alex Ellery via GIPHY

"We have looked at vacuum tubes because trying to create solid-state electronics would be virtually impossible on the moon," Ellery said. "If you use vacuum tubes, the only materials you need are nickel, tungsten, glass, essentially, and Kovar, all of which you can make on the moon."

Ellery says that the self-replicating machine would use a neural network — a computing system modeled after the human brain — because it would be smaller and easier to 3D-print than a typical computing system. The Carleton team has built a trial neural network and used it to control a small rover.

"Once motors and electronic controllers can be 3D-printed, we can print any kind of robot, including a 3D printer, as well as milling machines, drills, lathes, excavating machines and so on," Ellery said. "If you have a robotic self-replicating machine, you can grow an enormous manufacturing infrastructure on the moon robotically."

Such a machine could build habitats for astronauts before they arrive at a deep- space location. It could also be used to cheaply enable space-based solar power, in which satellites equipped with solar panels turn sunlight into energy, and send that energy down to Earth. Humans could also build space shields to protect the Earth against solar radiation, which could further combat the planet's warming trend Ellery said.

Follow us @Spacedotcom, Facebook and Google+. Original article on Space.com.

'Secrets of the Penguins' will take penguin observations 'to another level,' executive producer James Cameron

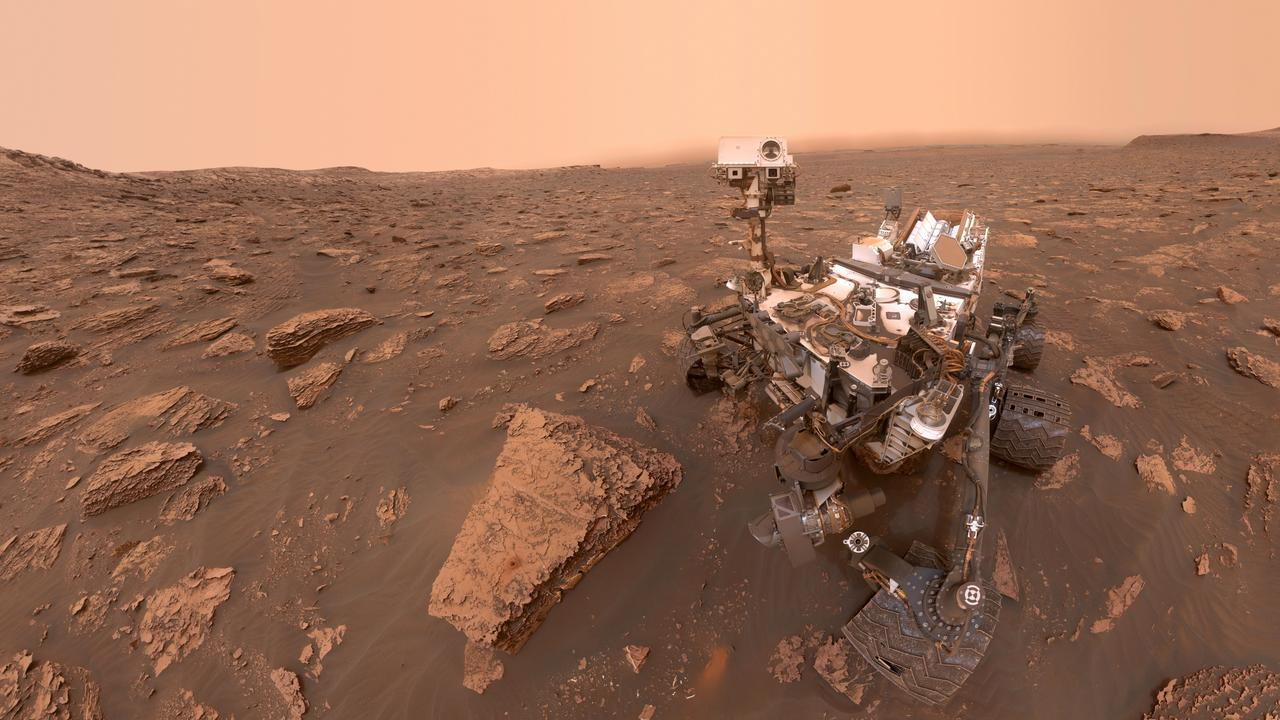

Curiosity rover finds largest carbon chains on Mars from 3.7-billion-year-old rock

Stabbed, cut, attacked, twisted — scientists subject new stretchable battery to extreme torture, and it retained 90% of its capacity