Harvard Printer Blasts Droplets with 100 Times Earth's Gravitational Force (Video)

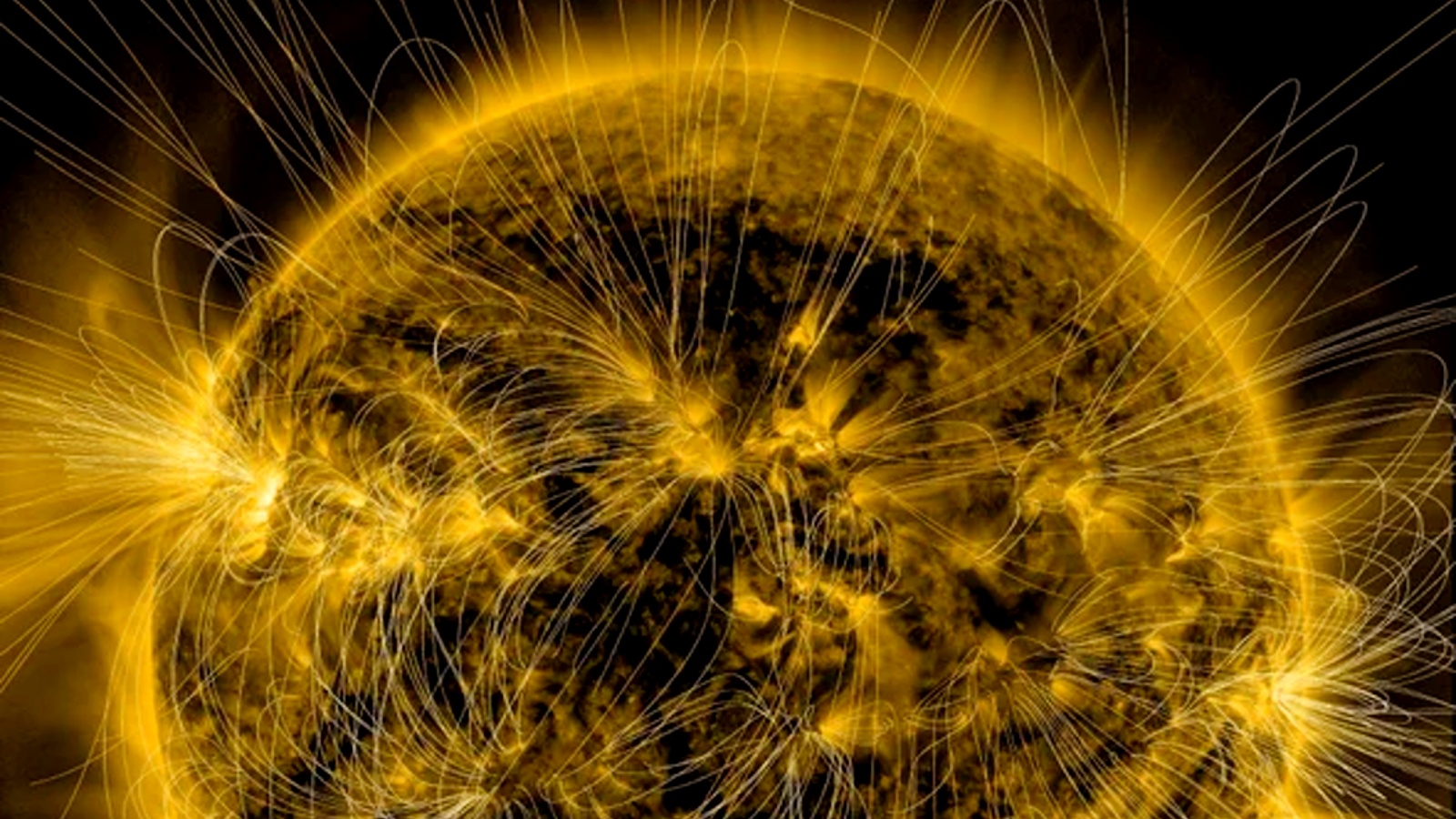

Stop a droplet. Let it grow. Then, pull on it harder than the gravity at the surface of the sun.

A new printing technique designed at Harvard University's engineering school uses sound waves to control and fire droplets from a nozzle with incredible force, allowing researchers to print with liquids thicker and more viscous than ever before. Honey, stem-cell-based inks and liquid metals all printed fluidly using these vibrations, which come from acoustic techniques that researchers had previously used to levitate liquids, not print with them.

The new technique was described in a paper published today (Aug. 31) in the journal Science Advances.

As Live Science has previously reported, sound waves exert pressure on the objects they crash into. Researchers have long experimented with fine-tuning that pressure to push and pull on things, levitate them or even build tractor beams. (You can try it at home.) In the new study, the researchers used that same pressure to precisely control the ink inside a printer, vastly expanding the range of liquids it could print with. [6 Weird Facts About Gravity]

"Our goal was to take viscosity [the thickness of the liquid] out of the picture by developing a printing system that is independent from the material properties of the fluid," lead study author Daniele Foresti, a research associate in materials science and mechanical engineering at Harvard University's School of Engineering and Applied Sciences, said in a statement.

Under normal circumstances, printers rely on gravity to form droplets of ink and deposit them, according to the study. That's effective up to a point, but it limits the materials a printer can use; a printer designed to deposit droplets of fast-flowing ink wouldn't do a very good job with much slower-dripping pitch.

The scientists said that past acoustic printing experiments have used sound waves to form droplets but offered only limited control over them.

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

For their new method to work, the researchers tuned sound waves that would capture droplets from a nozzle and fire them only after the drops had grown to the proper size. And that firing is intense: The researchers wrote that their system accelerates droplets with more than 100 times Earth's gravitational force at sea level (close to 1,000 meters per second squared) — or about 3.5 times the sun's surface gravity of 274 m/s^2.

"The idea is to generate an acoustic field that literally detaches tiny droplets from the nozzle, much like picking apples from a tree," Foresti said.

No matter how thick or thin the liquid, once it reaches the proper size, the sound waves capture it, the study said.

The researchers wrote that pharmaceutical companies seeking precise control over materials like stem cells should be the first to benefit from their new printing method, but that they expect it to be useful in all sorts of industries that work with viscous materials.

Originally published on Live Science.