New reactor could more than triple the yield of one of the world's most valuable chemicals

A new reactor creates ammonia from polluted wastewater using electricity, and it's way more efficient than existing methods.

Get the world’s most fascinating discoveries delivered straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered Daily

Daily Newsletter

Sign up for the latest discoveries, groundbreaking research and fascinating breakthroughs that impact you and the wider world direct to your inbox.

Once a week

Life's Little Mysteries

Feed your curiosity with an exclusive mystery every week, solved with science and delivered direct to your inbox before it's seen anywhere else.

Once a week

How It Works

Sign up to our free science & technology newsletter for your weekly fix of fascinating articles, quick quizzes, amazing images, and more

Delivered daily

Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

A new reactor could turn wastewater into drinking water — while also generating one of the world's most sought-after chemicals.

The new reactor, described Aug. 12 in the journal Nature Catalysis, produces ammonia gas from water contaminated with nitrate ions.

Ammonia (NH3) is an extremely important industrial chemical. It is one of the key components in fertilizers and also vital in chemical manufacturing processes. Over 180 million tons (163 million metric tons) are produced annually, mostly by the 100-year-old Haber-Bosch process, a high temperature-high pressure reaction between hydrogen and nitrogen. This one chemical reaction alone uses approximately 2% of the world's energy, according to the study.

Nitrate, on the other hand, pollutes rivers and streams when excess runoff from fertilized farmland enters local waterways. Nitrates devastate aquatic ecosystems, and at higher levels in drinking water can pose health risks. To be safe to drink, water must be thoroughly treated to remove nitrates.

Existing commercial treatments use bacteria to convert nitrate ions directly to nitrogen, but this procedure is expensive and also produces nitrous oxide, which, pound for pound, is 265 times more potent as a greenhouse gas than carbon dioxide.

To avoid this climate impact, scientists are working on ways to convert nitrate into ammonia using electricity, but early systems have struggled with unwanted side reactions.

In these devices, there is a positive and negative end, with a difference in charge between the two. Chemical reactions occur at both. Water is split into oxygen gas and hydrogen ions at the negative end of the reactor, while a second reaction converts nitrates to ammonia and hydroxyl ions (OH-) at the positive end.

Get the world’s most fascinating discoveries delivered straight to your inbox.

Unfortunately, hydrogen ions produced on one side tend to diffuse to the other, where they chemically react to form hydrogen. Because even highly polluted water still has tiny concentrations of nitrate, this hydrogen reaction winds up dominating and prevents the main nitrate-to-ammonia reaction from occuring efficiently. Scientists have tried to get around this by putting additives into the mix, but this is impractical for real-world applications in water treatment.

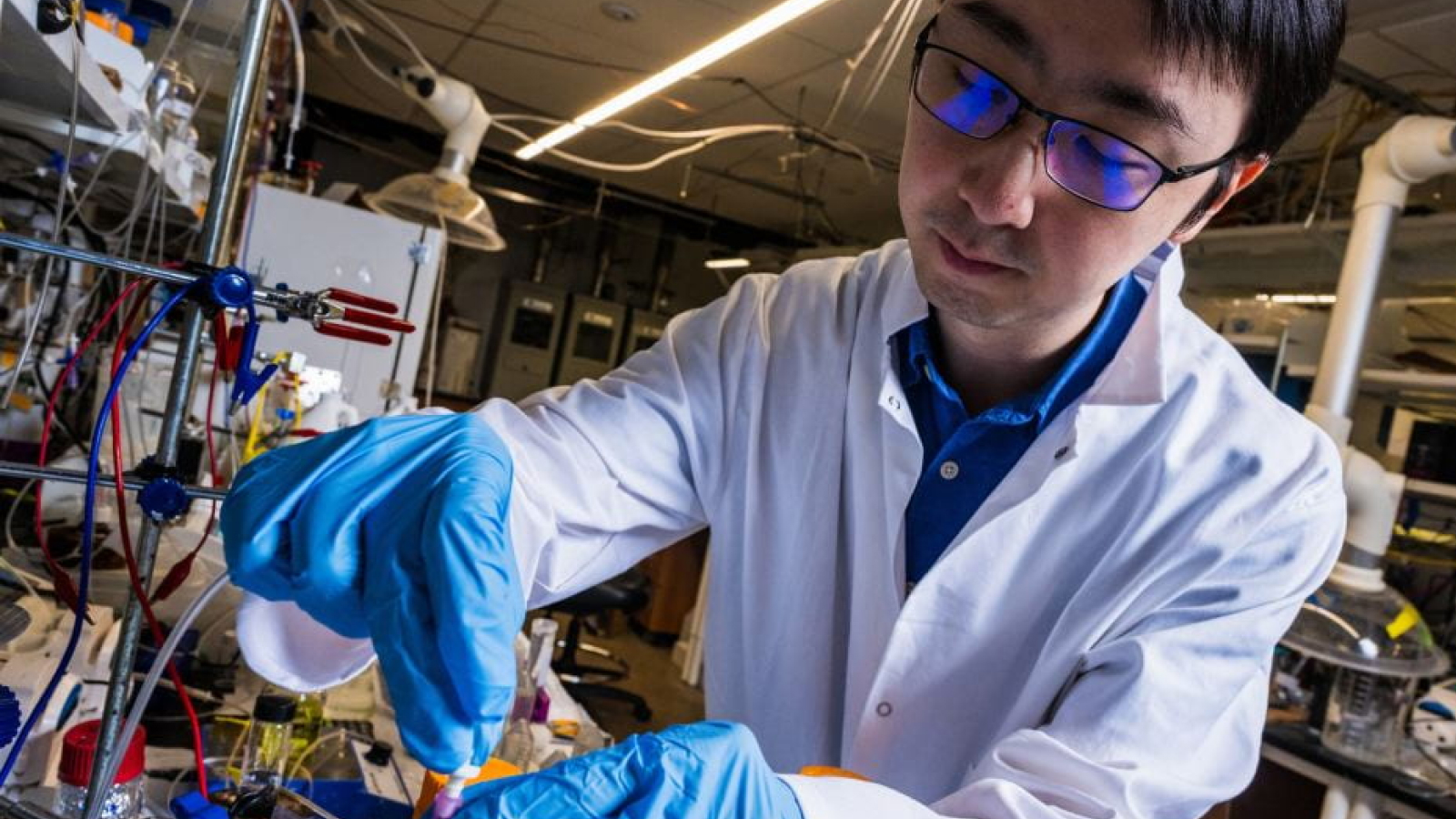

In the new study, the researchers got around this problem in part by adding an intermediate chamber, creating a three-chamber reactor, study first author Feng-Yang Chen, a researcher at Rice University in Texas, told Live Science in an email. In the first chamber, nitrate is converted into ammonia gas and hydroxyl ions. These combine with sodium ions already present in the water to form sodium hydroxide. As the cleaned water leaves the first chamber and is pumped into the middle chamber with this sodium hydroxide, the newly-formed ammonia gas is bubbled out. Meanwhile, in the third chamber, hydrogen ions produced by the splitting of water diffuse across the cell into the middle chamber. Here, hydrogen and hydroxyl ions from the sodium hydroxide combine to form water. The leftover sodium ions then move back from the middle chamber into the first chamber to repeat the cycle.

Crucially, no hydrogen ions reach the other side of the reactor to interfere with the nitrate reaction. In a 10-day test run, over 90% of the electric current in the research team's cell powered ammonia production, compared with around 20% for former systems.

Wang's design is still experimental and they still need to work out several issues before the technology can be rolled out commercially.

One of the big challenges is ensuring the reaction can still proceed in the presence of impurities, such as magnesium and calcium ions, that are often found in water, Chen said.

Victoria Atkinson is a freelance science journalist, specializing in chemistry and its interface with the natural and human-made worlds. Currently based in York (UK), she formerly worked as a science content developer at the University of Oxford, and later as a member of the Chemistry World editorial team. Since becoming a freelancer, Victoria has expanded her focus to explore topics from across the sciences and has also worked with Chemistry Review, Neon Squid Publishing and the Open University, amongst others. She has a DPhil in organic chemistry from the University of Oxford.

Live Science Plus

Live Science Plus