Amazingly simple discovery extends Li-ion battery lifespan by 50% — meaning you don't have to replace your gadgets as often

Batteries used in smartphones or in EVs normally charge for 10 hours on their first cycle, but turbo-charging them to 100% capacity in 20 minutes may lead to a 50% longer lifespan.

Replacing gadgets like smartphones or laptops just because the battery stops holding charge can be a real headache. But new research outlines a way to give common lithium-ion batteries a much longer lifespan — starting with their very first charge cycle.

Charging Li-ion batteries — which power most personal electronics and electric vehicles (EVs) — at high temperatures or currents before they hit the shelves could extend their average lifespans by 50%, researchers said in a new study published Aug. 29 in the journal Joule.

The results "demonstrate a generalizable approach for understanding and optimizing this crucial step in battery manufacturing," said study coauthor Steven Torrisi, a senior research scientist at the Toyota Research Institute in California, in a statement.

A typical Li-ion battery has a positive and a negative electrode in an electrolyte solution containing lithium ions. When you charge the battery, lithium ions move into the negative electrode. Then, when you use the battery and expend its charge, the lithium ions move out of the negative electrode and into the positive one. The back-and-forth flow of ions facilitates the electric current that powers a device.

Related: Charging future EVs could take seconds with new sodium-ion battery

A brand-new Li-ion battery is completely discharged — the positive electrode is full of lithium, and the negative electrode has plenty of space for lithium ions to flow into. But on the first charge, some of the lithium in the battery gets stuck on the surface of the negative electrode. The trapped lithium, along with other components of the electrolyte solution, becomes part of a layer called the solid electrolyte interphase (SEI). This SEI encases the negative electrode, protecting it from side reactions that cause further loss of lithium and so shorten the battery’s lifespan.

Usually, manufacturers first charge the battery slowly to build up a stable SEI. But that isn’t always the most cost-effective approach — and recent studies show that charging the battery quickly doesn’t necessarily have a negative impact on the battery’s life. What’s more, several other parameters can impact the SEI, so it’s not easy to optimize the first charge for the best battery performance.

Sign up for the Live Science daily newsletter now

Get the world’s most fascinating discoveries delivered straight to your inbox.

In the new study, researchers used machine learning to pick out the parameters that have the strongest effect on the SEI. Two factors — the current and temperature during the first charge — grabbed their attention.

Charging the battery over about 20 minutes, instead of the usual 10 hours or so, extended the battery’s overall lifetime by about 50%. More lithium gets stuck in the SEI on the first charge, but that limits the possibility of future side reactions that can shorten the battery’s life on subsequent cycles.

Raising the temperature from room temperature to 131 degrees Fahrenheit (55 degrees Celsius) had a similar effect, improving the battery’s lifespan by an average of 57%. That improvement likely comes from changes in the SEI composition that make it more robust, the researchers said. However, the techniques didn't synergize: charging the cell both quickly and at high temperatures didn’t improve battery performance.

"We didn’t just want to identify the best recipe for making a good battery; we wanted to understand how and why it works," said study coauthor Will Chueh, a materials scientist at Stanford University, in the statement. "This understanding is crucial for finding the best balance between battery performance and manufacturing efficiency."

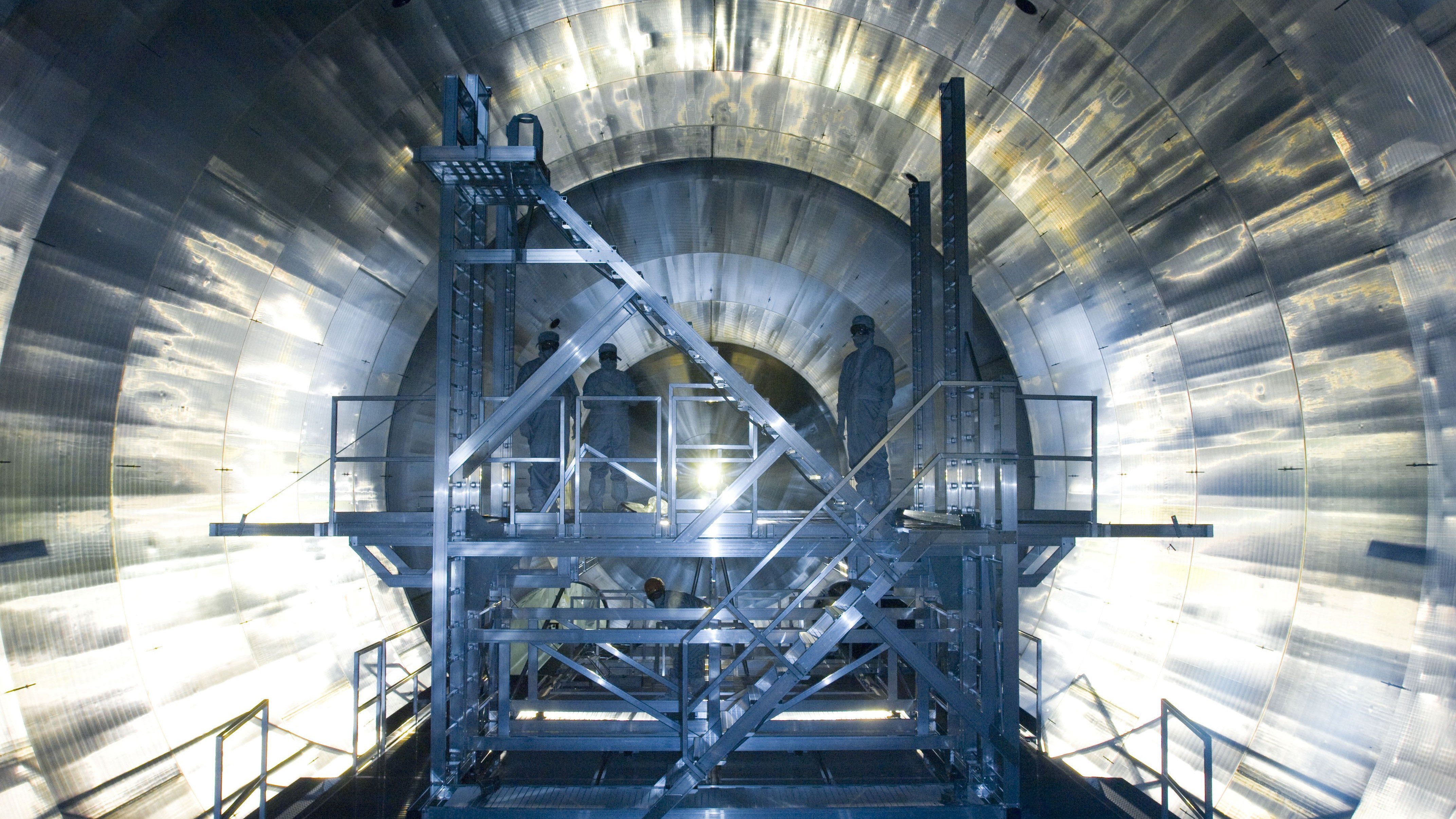

The new strategy could make batteries cheaper too, Chueh said. “This is an excellent example of how [the Stanford Linear Accelerator Center] is doing manufacturing science to make critical technologies for the energy transition more affordable,” he noted. “We’re solving a real challenge that industry is facing.”

Skyler Ware is a freelance science journalist covering chemistry, biology, paleontology and Earth science. She was a 2023 AAAS Mass Media Science and Engineering Fellow at Science News. Her work has also appeared in Science News Explores, ZME Science and Chembites, among others. Skyler has a Ph.D. in chemistry from Caltech.